Continuous Solvent Recycling: For Efficient Solvent Recycling

Reduce Solvent Costs by Up to 95% with Continuous Solvent Recycling

Slash Costs, Stay Green, and Simplify Compliance—All at Once.

Are rising costs eating into your profits? Regulators demanding eco-friendly solutions? You don’t have to choose between staying competitive and keeping the planet (and authorities) happy.

Maratek’s Solvent Saver Continuous (SSC) recycling units recover up to 95% of your used solvents—automatically.

Say goodbye to waste and hello to savings with equipment that works seamlessly in the background, requiring almost zero operator effort.

Recycle smarter, not harder.

From acetone to alcohols, our SSC line transforms any contaminated solvent stream back to its original quality—efficiently, economically, and tailored to your production process. Cut disposal costs, boost sustainability, and get ahead of regulations with one powerful solution.

Ready to save 95% on solvents? Get your free quote now and see the difference today!

Industry-Leading Automation: Save Time & Labor Costs

Recycle Up to 100+ Gallons/Hour—Hands-Free and Custom-Fit for You.

Imagine recovering 5 to 100+ gallons of solvent per hour with almost no effort. Maratek’s Solvent Saver Continuous (SSC) units do just that—running automatically so you don’t have to. Not sure what size fits your needs? Our experts will analyze your waste stream and match you with the perfect solution, fast.

Imagine recovering 5 to 100+ gallons of solvent per hour with almost no effort. Maratek’s Solvent Saver Continuous (SSC) units do just that—running automatically so you don’t have to. Not sure what size fits your needs? Our experts will analyze your waste stream and match you with the perfect solution, fast.

Built smarter for your bottom line.

These units handle acetone and beyond with no bags, advanced automations (outpacing Batch Premium models), and internal scrapers that tackle viscous waste buildup effortlessly. You get clean, recycled solvent without the hassle.

Tough, flexible, and ready to roll.

Crafted from 304 and 316 stainless steel, SSC units come air-cooled for smaller setups (swap to water at no extra cost) or water-cooled for larger systems—chilling water included if you need it. With customizable heating and condensing options, they integrate seamlessly into any industrial process.

Stop wasting solvent and start saving. Contact us now for a free assessment and see how SSC can transform your operation today!

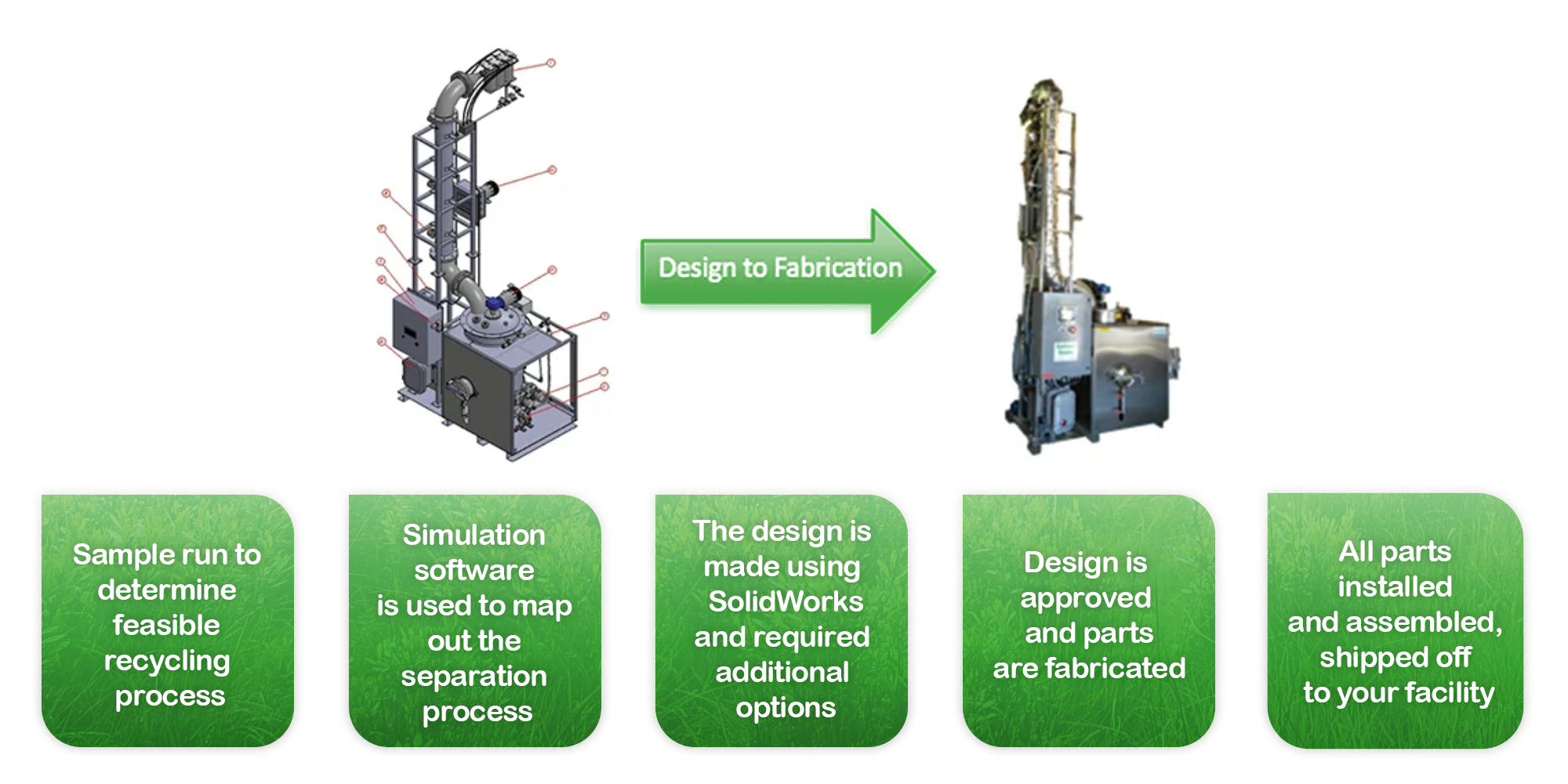

See How Simple It Works: 6-Step Recycling Process

Automated Recycling Process: With Minimal Operator Intervention

Maratek’s solvent recycling SSC models separate solvents using the proven process of distillation, as shown through the numbered illustration below.

- The waste solvent is automatically pumped into the distillation vessel.

- The distillation vessel is fitted with a jacket of thermal oil that is heated by one or more electric heaters which brings the waste solvent to its boiling point.

- Pure solvent vapors are then channeled to an air cooled condenser, where it cools into its liquid form.

- The liquid is then directed to the clean solvent collection drums, where it can be re-used.

- As solvent is recovered new waste is automatically fed into the unit without operator intervention.

- Once solvent recovery is complete the waste sludge is automatically discharged to a waiting drum/tote below.

How Much Can You Save? Find Out Now! Free Return On Investment Calculator.

.png?width=300&height=424&name=Maratek%20Case%20Study%20PPG%20(1).png)

Read our Case Study

See how PPG solved complex solvent waste challenges and reduced operational costs using Maratek’s SSC‑125 Solvent Saver System. This case study highlights how large-scale paint manufacturers can recover hundreds of gallons of solvents daily while improving safety and sustainability.

Read the full case study to learn how solvent recovery delivered measurable savings without upfront capital investment.

Industrial Blogs

Transforming Cabinet Manufacturing with Maratek’s Solvent Recovery

Maratek continuously strives to innovate and provide efficient solutions for industrial manufacturers, including the cabinet manufacturing industry.

Learn More

Batch vs Continuous Distillation: What is the Best Option?

Recycling solvents on-site through distillation can provide various benefits for businesses in the industrial manufacturing sector. It will result in significantly lower waste costs and allow businesses to market themselves as environmentally friendly.

Learn More

The True Value of Onsite Solvent Recycling and Recovery

Industrial manufacturers considering solvent recycling and waste management may have questions about the cost. When discussing finances, it is easy to get distracted by the upfront costs, but solvent recycling provides many long-term benefits that outweigh that initial upfront expense.

Learn More