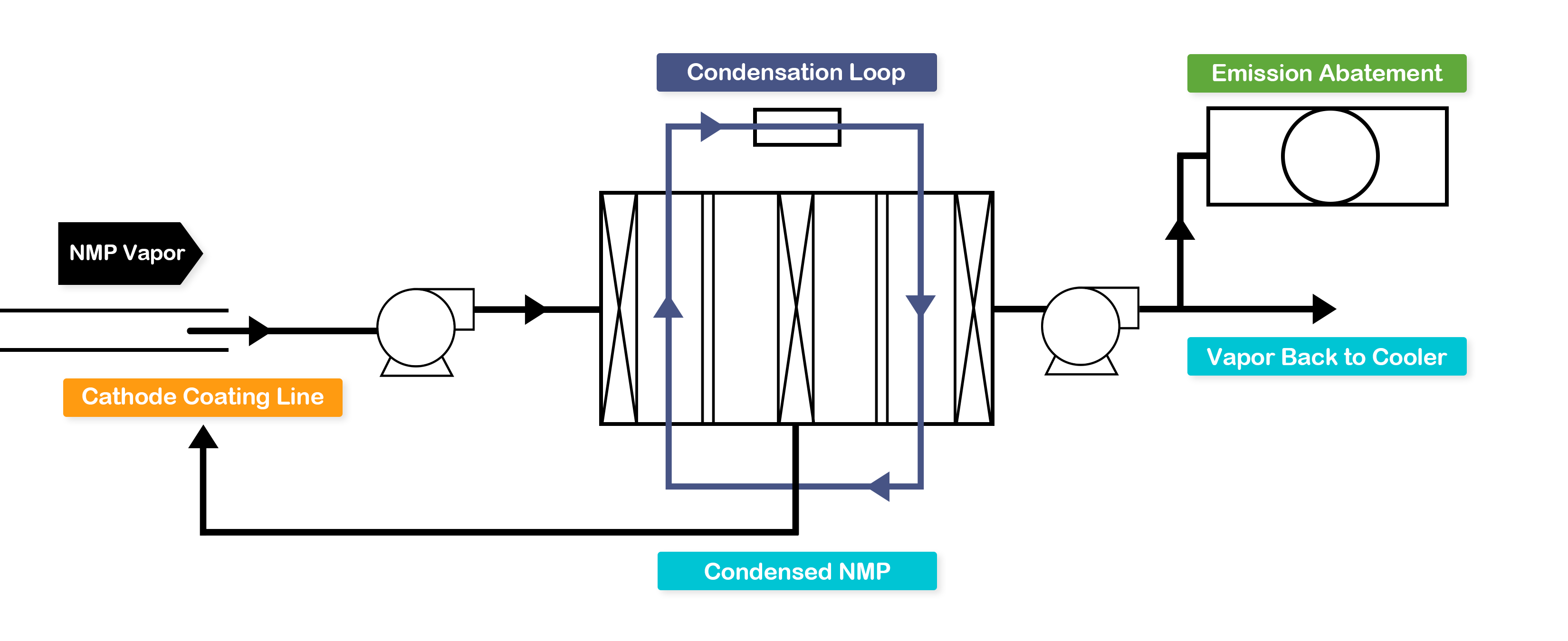

Optimized VOC Capture & Emission Abatement with Automation

Maratek’s automated VOC capture and emission abatement system recovers NMP, alcohols, acetone, and other solvent vapors with 99.9% purity, delivering:

-

Up to 95% cost savings by reusing high-purity solvents

-

Fully automated operation with minimal operator involvement

-

Regulatory compliance through efficient emission control

Key Features

-

High-Efficiency Recovery: Achieves 99.9% pure condensate without scrubbers, sieves, or carbon filters.

-

Customized Design: Tailored to your waste stream with closed-loop oven integration, plus options for refrigerated or cryogenic condensation.

-

Robust Construction: Built with 304/316 stainless steel for durability.

-

Advanced Controls: Supports Allen-Bradley, Siemens, and other digital systems with remote access, data logging, and unattended operation.

-

Versatile Applications: Easily integrates into industrial processes like battery manufacturing, coatings, and more.

Trusted globally, Maratek’s custom-engineered solutions ensure rapid ROI with free assessments and rental options.