Solvent Saver Batch Recycling Unit

Save Up to 95% on Solvent Costs - Industrial Recycling Solution

Maratek proudly presents the Solvent Saver Batch (SSB) series, meticulously engineered to revolutionize waste solvent management. Our SSB units expertly separate waste solvents into reusable resources and waste residue, delivering exceptional performance with effortless operation and maintenance. Plug it in, start it up, and witness your savings take flight!

From acetone to white spirits and beyond, our Solvent Saver models restore contaminated solvents to their original, pristine condition, seamlessly reintegrating them into your production processes. Reclaim up to 95% of your waste solvent stream, transforming waste into a valuable asset.

In today’s industries, waste solvents are a common byproduct – but they don’t have to be a loss. Maratek’s Solvent Saver Batch line is designed to turn this challenge into an opportunity, efficiently recycling solvents for reuse while isolating residue with precision.

Built for flexibility, our Batch units run one cycle at a time, putting you in control of the schedule. For operations with lower waste output, the SSB stores waste internally until you’re ready to process, offering unmatched convenience and efficiency tailored to your needs.

Download the brochure now.

Choose Your Perfect Solution: Batch vs Batch Premium

Our Batch and Batch Premium units are meant for different levels of difficulty. For simple applications with minimal automations we usually suggest our Batch units. For more difficult to manage waste recycling or when some level of automation is desired we may suggest our Batch Premium units.

Our Batch models come in 8, 16, 32, 48, and 64 gallon sizes, so we are able to accommodate all industries and applications.

Included in Every Unit: Premium Features That Save You Money

- Safety Features & Temperature Controls using a variety of sensors and automations all of our SSB units are able to run safely with minimal operator intervention.

- Class I Div I Group D Explosion Proof all systems are certified Class I Div I Group D explosion proof.

- Electric Heating With Thermal Oil using a thermal oil jacket, electric heaters quickly and evenly heat the boiling vessel.

- Batch units include a small mounted button control system which allows for temperature and batch length settings.

Customize Your Unit: Power-Up Options for Maximum Efficiency

- Vacuum Assistance

- Nitrocellulose Safety Features

- Water / Solvent Separator

- Automatic Filling (included with Batch Premium)

- Stainless Steel Condenser (included with Batch Premium)

How It Works: Simple 4-Step Solvent Recovery Process

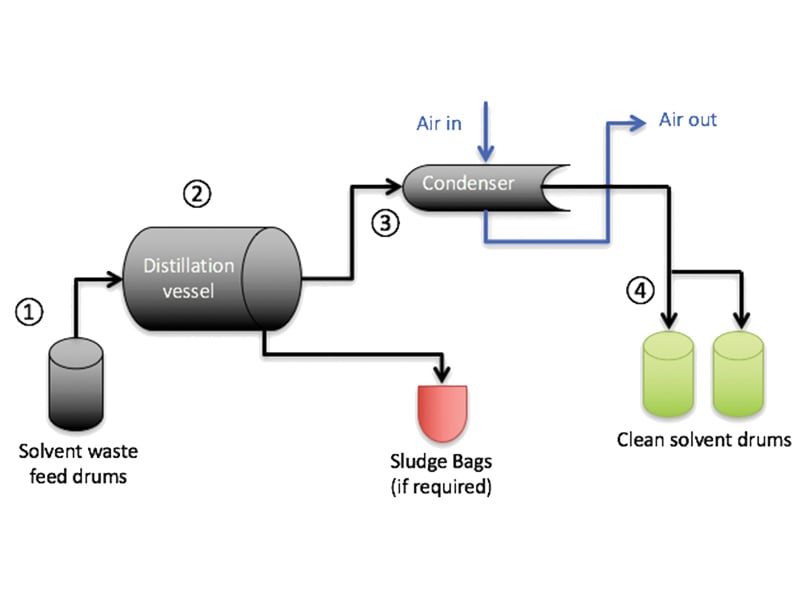

Maratek’s solvent recycling SSB models separate solvents using the proven process of distillation, as shown through the numbered illustration below.

- The waste solvent is fed or manually poured into the distillation vessel.

- The distillation vessel uses a thermal oil jacket that is heated by one or more electric heaters which brings the waste solvent to its boiling point.

- Pure solvent vapors are then channeled to an air cooled condenser, where it cools into its liquid form.

- The liquid is then directed to the clean solvent collection drums, where it can be re-used.

How Much Can You Save? Find Out Now! Free Return On Investment Calculator.

.png)

Read our Case Study

See how the Minnesota Department of Transportation streamlined asphalt testing and reduced solvent costs using Maratek’s compact SSB‑6 Solvent Saver System. This case study highlights how government and infrastructure labs can reliably recover nPB on‑site while improving workflow efficiency and sustainability.

Read the full case study to learn how low‑volume solvent recovery delivered measurable savings with simple, long‑term operation.

Industrial Blogs

3 Important Factors to Improve Solvent Recycling Efficiency

Over the past few decades, the manufacturing industry has seen the introduction of solvent recycling technology. But what should your organization look for when purchasing solvent recycling.

Learn More

Batch vs Continuous Distillation: What is the Best Option?

Recycling solvents on-site through distillation can provide various benefits for businesses in the industrial manufacturing sector. It will result in significantly lower waste costs and allow businesses to market themselves as environmentally friendly.

Learn More

5 Factors for Choosing Solvent Recycling Equipment for your Company

The process of selecting solvent recycling equipment for your company’s unique requirements can be an arduous process, with many different factors coming into play, from the volume of recycling to how often you will be operating the system.

Learn More