Process Design

Determine Effective Solutions with Process Simulations

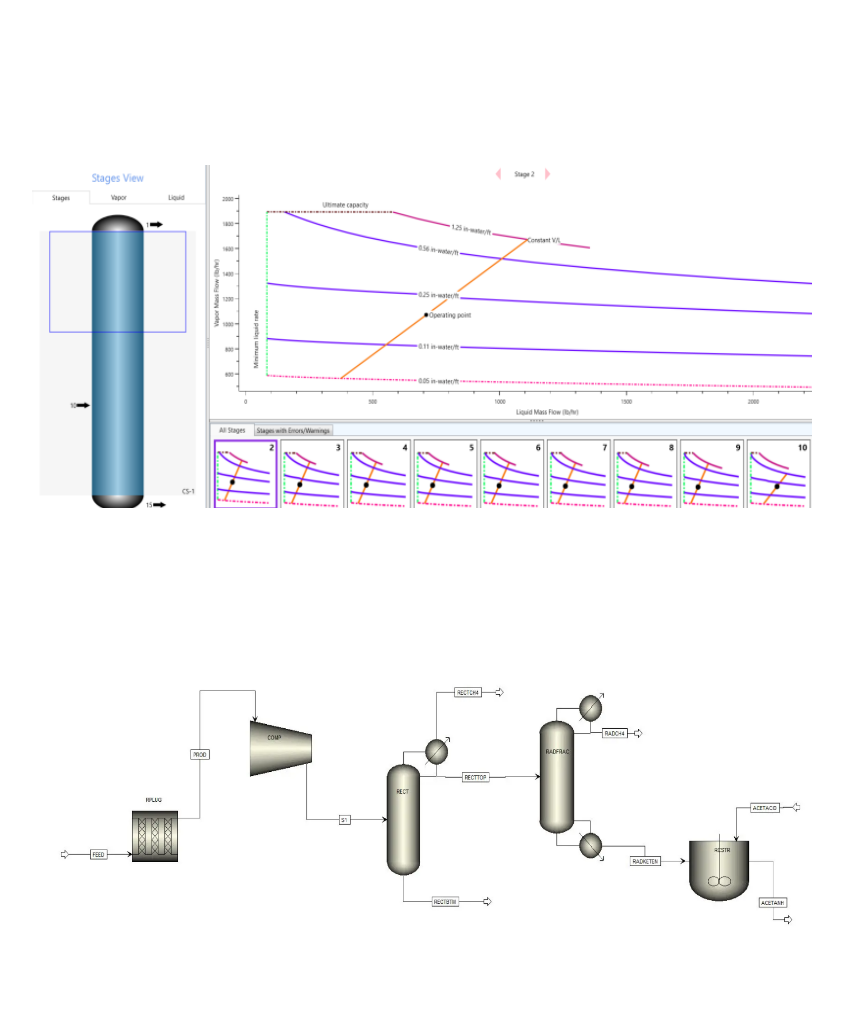

Maratek’s engineering team uses Aspen HYSYS to simulate a wide variety of applications from batch distillation to complex fractional distillation processes. Simulations are an imitation of the dynamics of real-world processes or systems. They serve as a pivotal tool in the conception and refinement of industrial chemical processes.

Virtual experiments conducted through simulation models offer a means to explore diverse scenarios swiftly, safely, and cost-effectively, in stark contrast to real-world testing. These simulations emulate real-world process dynamics, facilitating experimentation to fine-tune a system's operational parameters.

Amidst mounting pressure to reduce environmental footprints and adhere to stringent regulations, our team specializes in crafting processes that minimize waste generation, optimize resource utilization, and align with environmental regulatory standards. By harnessing process simulations, Maratek assists manufacturers in identifying eco-friendly alternatives and implementing sustainable practices, fostering a greener industry through innovative technology.

Maratek's engineers are up to the task to determine the best process for your application and help you achieve your goals. Get a quote today or contact us with any questions that you may have.

Benefits of Process Simulation

- Process and Control Simulation: Performing testing and training on new processes, designs, and parameters helps to shorten commissioning time at start up and facilitates in conducting sensitivity analysis with extreme conditions.

- Enhanced Safety: Reduce the risks before commissioning by allowing users to gain familiarity, optimize the processes and operational competencies before deploying to offshore locations.

- Comprehensive Scenario Testing: Decrease or eliminate shut down time by providing operators the opportunity to test proposed process updates and operational changes. As well as reducing maintenance costs by identifying issues within the simulation instead of in the plant.

- Improved Operator Training: A virtual simulation identical to plant operations can be created to enhance operator performance through safe, practical, offline training and skill development.

- Lifecycle Simulation: Predict the consequences of design changes, parameter modifications, flow rate change, new commissioning, and validate optimization before real world execution.

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi non commodo mauris.

Solvent Recycling: Do You Need a Custom Engineering Solution?

Many waste streams require tailored solutions. Built-to-order and custom enginrering can address your needs.

Learn More

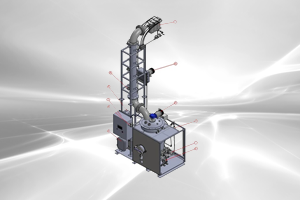

Enhancing Industrial Production with Maratek's Engineering Services

Using technology, Maratek's engineers craft process simulations, renders, and designs to help industrial manufacturers.

Learn More

Custom Solvent Recycling Equipment at Maratek Environmental

Maratek offers simulation, design, fabrication, testing and set-up with our team of engineers.

Learn More

Success Stories: Real Results from Industry Leaders

The Solvent Saver 300 system Maratek installed here at Colorado Printing is working extremely well. It has lived up to every Maratek claim. We had tried another system that was nothing but headache after headache. We are pleased the Maratek Solvent Saver was able to help us reclaim our waste solvents.

Steve Brewer

Colorado Printing

I am pleased with Maratek's automatic recycling unit and service department. They have enabled us to clean up our contaminated solvent waste so that we can reuse it on-site.

Pro Form Products Ltd.

The Maratek Solvent Saver was installed just over 3 years ago and I can say it has lived up to its claims of being able to provide quality recovered solvent for reuse on our Heidelberg sheetfed presses. We had looked at other systems but the flexibility, small space requirements, and being able to use our current solvent without switching made the Maratek system our final choice. We feel we made the right decision. Lake Country Press believes in doing its part in helping our environment, the Maratek Solvent Saver definitely plays a big part in our environmental and cost saving initiatives.

Lake Country Press

We have had the Maratek Solvent Saver for several years now and without a doubt it helped us achieve and maintain lower waste generator status and make our waste volume more manageable. I allow tours for Maratek because I am proud of what it does for us and feel everyone that creates solvent waste should have a Maratek System.

Standard Printing Company

Maratek's unit has worked really well. We have been using it to recycle toluene from road paints, but most surprising of all - we can't believe how quiet it is.

City of Burnaby

We have had very few issues with our recycling unit. The installation and on-site setup was simple and fast.

Auria Solutions