Battery Manufacturing - Fractional Distillation

Fractional Distillation for Battery Solvent Recovery

Maratek’s fractional distillation columns are custom-engineered to recover valuable solvents like NMP, Ethanol, Acetone, and Hexane from battery manufacturing waste streams, delivering:

-

Up to 95% cost savings by reusing high-purity solvents

-

Exceptional purity through precise separation of complex mixtures

-

Sustainable operations with reduced waste and regulatory compliance

Why Maratek’s Fractional Distillation?

-

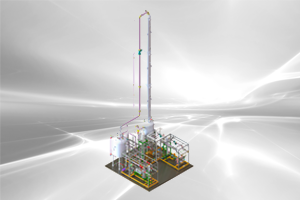

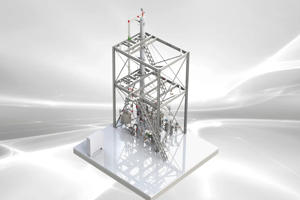

Tailored Design: Optimized using Aspen HYSYS and SolidWorks for your specific waste stream, from 1 to 500+ gallons per hour.

-

Advanced Separation: Leverages boiling point differences to dewater and purify challenging mixtures like NMP.

-

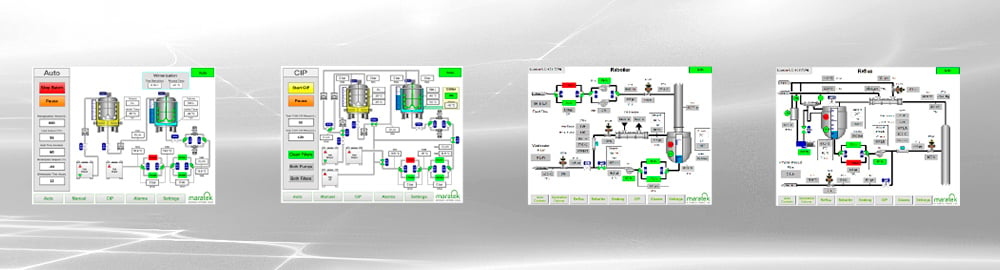

Automated Efficiency: Fully automated systems minimize operator involvement and maximize output.

-

Scalable Solutions: Custom-built for complex mixtures or high-capacity needs, backed by 50+ years of engineering expertise.

Trusted globally, Maratek empowers battery manufacturers with rapid ROI, free lab tests, and rental options for seamless integration.

Start Reclaiming Solvents: Request a Free Cost-Savings Analysis today to tailor our fractional distillation technology to your facility.

Maratek can also custom build, engineer and manufacture sizes above this capacity or for any complex mixtures that our clients are looking to separate. With over 50 years of engineering experience, Maratek can tackle any project, no matter the complexity.

Optimized Operating Principle:

Maratek’s Fractional Distillation

Maratek’s fractional distillation systems deliver fully automated, high-purity solvent recovery for battery manufacturing, achieving 99%+ purity for solvents like NMP, Ethanol, and Acetone. Here’s how they work:

-

Continuous Processing: Automatically processes feed, collecting solvent-rich distillate (top) and removing solvent-lean waste (bottom).

-

Vapor-Liquid Separation: Trays or packing in the column enable vapor-liquid equilibrium, separating solvents based on boiling points.

-

Enhanced Purity: Boil-up and reflux streams recirculate vapor and liquid to maximize solvent purity and process efficiency.

-

Custom Integration: Designed as stand-alone units or paired with Maratek’s Continuous Solvent Recycling Systems for seamless operation.

Equipped with state-of-the-art digital controls, our systems ensure reliable monitoring, operator safety, and regulatory compliance, while reducing costs by up to 95%.

Start Reclaiming Solvents: Request a Free Cost-Savings Analysis today to integrate Maratek’s distillation technology into your facility.

.png?width=1080&height=1080&name=Untitled%20design%20(7).png)

Separation of any Solvent Mixture, no Matter the Complexity

Reduce Solvent & Waste Disposal Costs

Improve Solvent Purity & Effectiveness

1-500+ Gallons/Hour of Solvent Reproofing

Continuous Fully Automatic Operation

Blogs

Solvent Recycling: What is Fractional Distillation?

Why is fractional distillation so important and how can you save your business money with this technology?

Learn More

3 Major Benefits of Fractional Distillation

Not sure about the benefits of fractional distillation? Check out this blog to identify the benefits.

Learn More

What is the Purity of Recycled Solvents?

Check out how you can find the right equipment for you depending on your solvent purity requirements.

Learn More