Solvent Saver Batch Premium

Solvent Saver Batch Premium (SSBP) Recycling Equipment

Discover the power of the Solvent Saver Batch Premium (SSBP) series, designed for seamless process automation. Our cutting-edge equipment effortlessly transforms waste solvents into valuable, reusable resources while isolating waste residue. Experience unparalleled ease of use and maintenance – simply plug it in, press start, and watch your efficiency and savings skyrocket!

Regardless of your solvent type – whether acetone, white spirits, or anything in between – our SSBP units expertly restore contaminated solvents to their pristine, original state, ready to reintegrate into your production line. Unlock the potential to reclaim up to 95% of your waste solvent stream, turning waste into opportunity.

Tailored for flexibility, the Solvent Saver Batch Premium operates on a single-cycle basis, giving you full control over its runtime. For lower waste volumes, the Batch design cleverly stores waste within the unit until you’re ready to process, ensuring maximum convenience and efficiency on your schedule.

Choose Your Perfect Solution: Batch vs Batch Premium

Our Batch and Batch Premium units are meant for different levels of difficulty. For simple applications with minimal automation we usually suggest our Batch units. For more difficult to manage waste recycling or when some level of automation is desired we may suggest our Batch Premium units.

Batch Premium models are available in 32 and 110 gallon sizes.

Standard Features for Batch Unit:

- Safety Features & Temperature Controls Using a variety of sensors and automations all of our SSB units are able to run safely with minimal operator intervention.

- Class I Div I Group D Explosion Proof All systems are certified Class I Div I Group D explosion proof.

- Electric Heating With Thermal Oil Using a thermal oil jacket, electric heaters quickly and evenly heat the boiling vessel.

- Batch Premium units include a touch screen PLC for highly automated operation.

- Autofill

- Stainless Steel Condenser

- Ethernet PLC for remote access, control and trouble shooting.

Enhance Your System:

Premium Add-ons Available

- Nitrocellulose Safety Features

- Water/Solvent Separator

- Anti-Spill Sensors

- Dual Container Filling and Collection

How Our Solvent Saver Technology Works: Simple 4-Step Proces

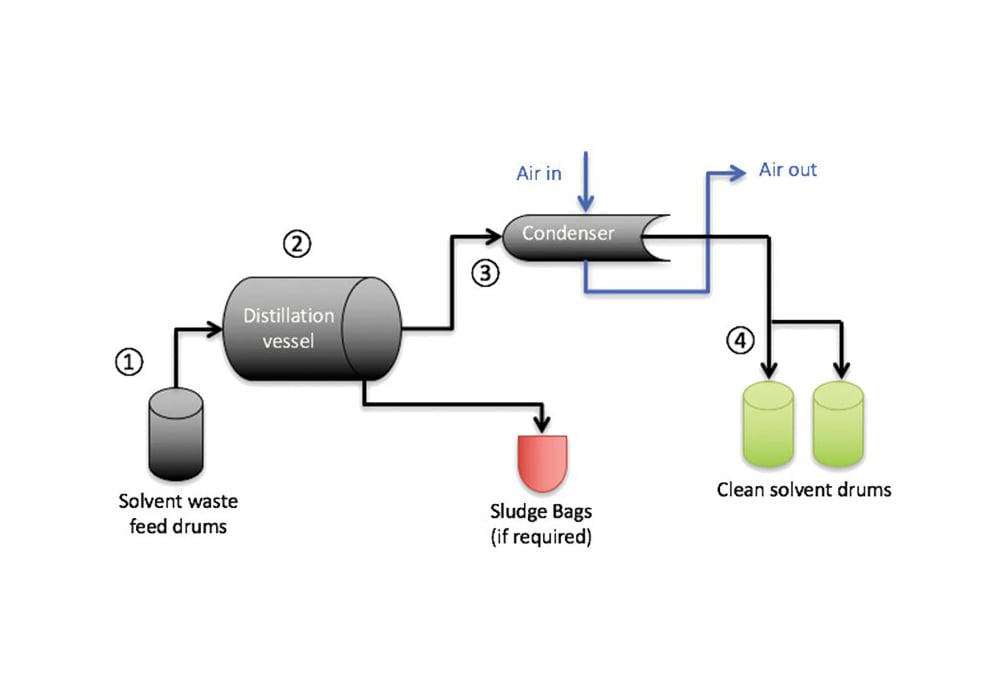

Maratek’s solvent recycling SSBP models separate solvents using the proven process of distillation, as shown through the numbered illustration below.

- The waste solvent is fed or manually poured into the distillation vessel.

- The distillation vessel uses a thermal oil jacket that is heated by one or more electric heaters which brings the waste solvent to its boiling point.

- Pure solvent vapors are then channeled to an air cooled condenser, where it cools into its liquid form.

- The liquid is then directed to the clean solvent collection drums, where it can be re-used.

How Much Can You Save? Find Out Now! Free Return On Investment Calculator.

Read our Case Study

See how Aerogel Technologies solved complex multi‑solvent recovery challenges using Maratek’s SSBP‑110 Solvent Saver Batch Premium System. This case study highlights how advanced materials manufacturers can safely recover mixed solvents while improving automation and compliance.

Read the full case study to learn how engineered solvent recovery boosted reliability and supported innovative product development.

Industrial Blogs

Can Recycling Mineral Spirits Save Your Facility Money?

Why Mineral Spirits Are Used in Parts Washing? Mineral spirits are a petroleum-based solvent used widely in manufacturing and maintenance.

Learn More

Solvent Saver Batch (SSB) Helps City in BC become Greener

The City of Burnaby has a designated road painting department that helps mark and line the pavement to guide traffic. Lane and center lining is carried out using a specially equipped truck.

Learn More

How to Determine Your Solvent Recycling ROI

As a business owner, ensuring maximum return on your investments is critical for avoiding losses and driving the growth of your company. At Maratek, we provide tools to help calculate your return on investment (ROI) if you decide to implement our solvent recycling systems.

Learn More