A Versatile Model with More Automation

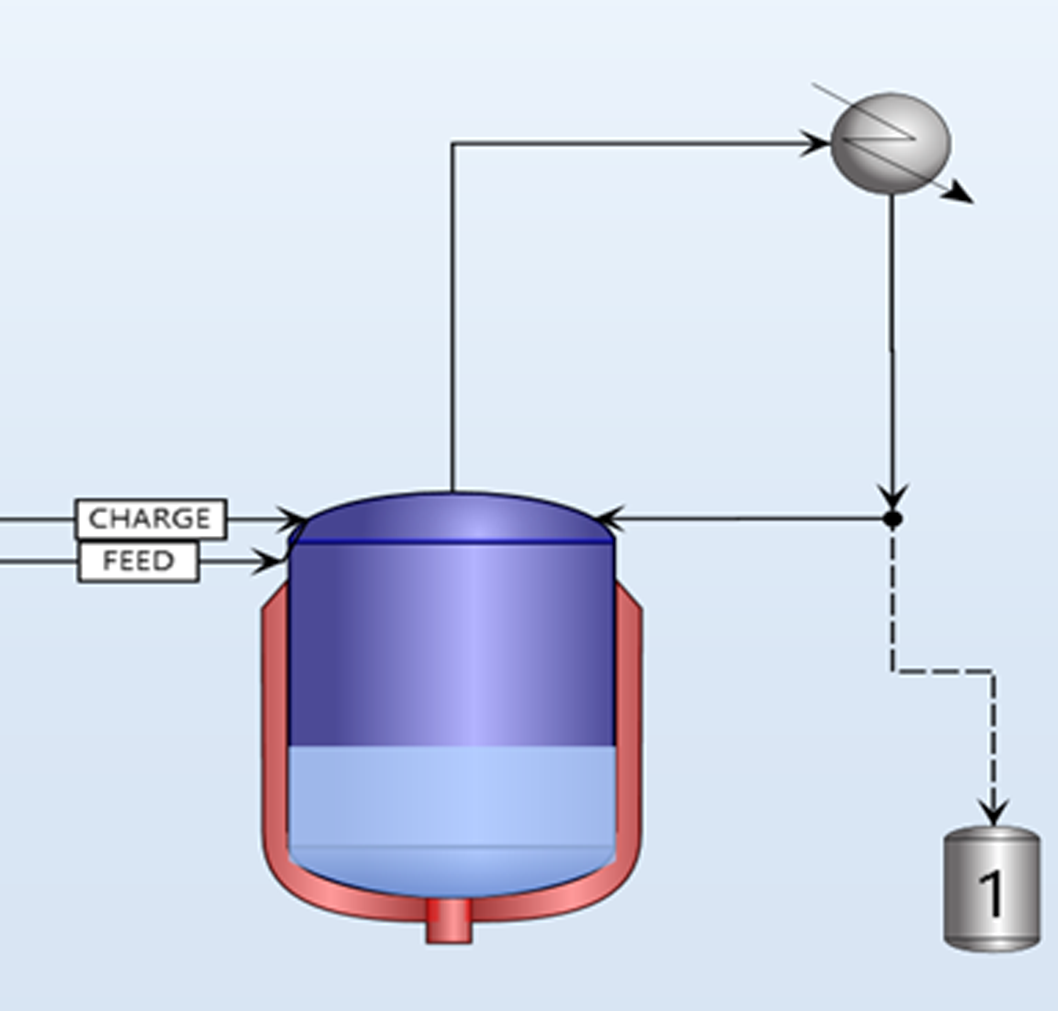

The single stage battery solvent recovery unit can recover between 5 to 100+ gallons/hour and operate virtually without an operator. To find the right size for your application our team will assess the characteristics of your waste stream.

These rates are assigned according to the reference chemical, acetone, without any contaminants. These models do not use bags and include many automations. Internal scrapers are also used to manage waste buildup inside the vessel and assist with discharge of viscous wastes.

All of these units are fully constructed of 304 and 316 stainless steels. Air cooling is standard for smaller sizes but can be changed to water without additional cost. Larger systems are water cooled systems and require a source of chilling water which can be provided by Maratek.

By selecting the appropriate options, these units can be tailored to fit a variety of applications and they can be integrated into most industrial uses. Maratek battery solvent recovery units can be configured with different heating and condensing mediums, making these units extremely versatile.