Industrial-Grade Fractional Distillation Systems:

Maximize Your Solvent Recovery

Transform Your Solvent Processing: 99.9% Pure Solvent Recovery with Advanced Purification Technology

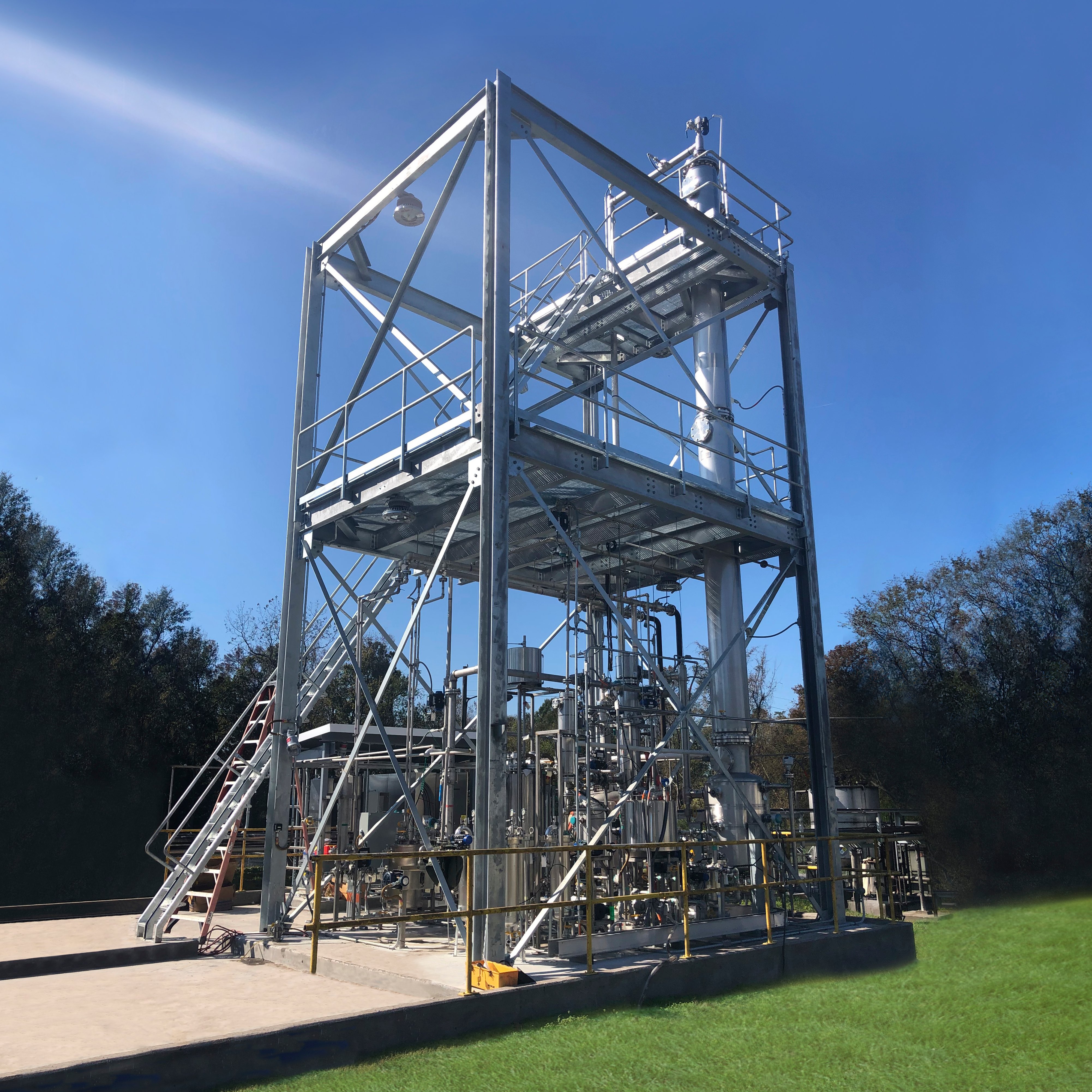

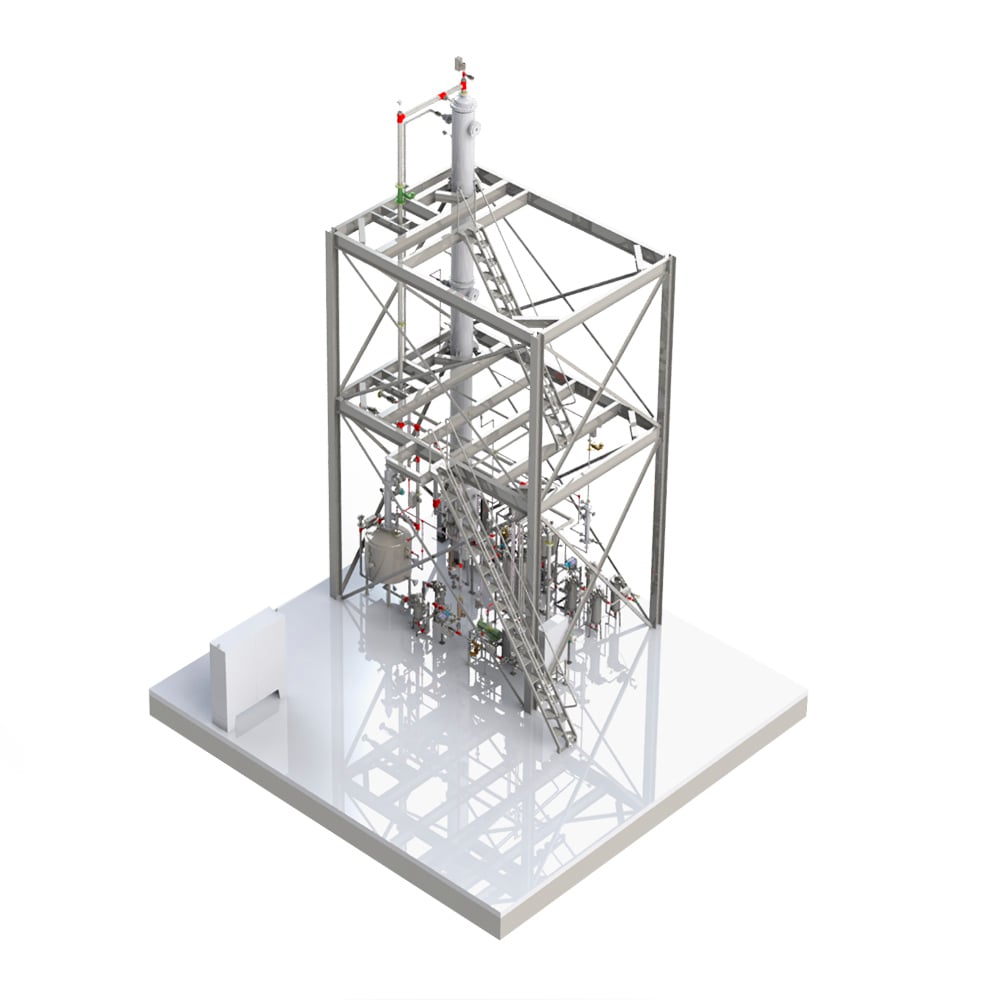

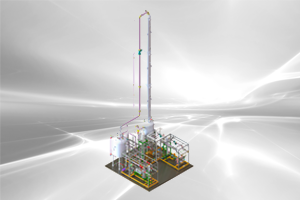

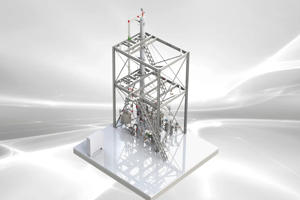

Maratek's Fractional Distillation Columns are uniquely designed by our in-house engineering team to be customizable to your solvent waste stream. This can include solvents like NMP, methanol, ethanol, and many others. Maratek’s team of engineers will use a variety of tools to properly test, assess, design and implement a custom on-site solution for you. These units are tailored to your company's unique facility, waste stream and goals. Our team will determine the appropriate method of recycling as well as a variety of features to provide a highly automated, user-friendly and highly efficient process.

The fractionation columns are generally used to ease the solvent separation process or to obtain higher purity recovered solvents. The engineering team at Maratek uses Aspen HYSYS and SolidWorks to design and implement the fractionation columns in order to optimize the solvent purity and recovery rate.

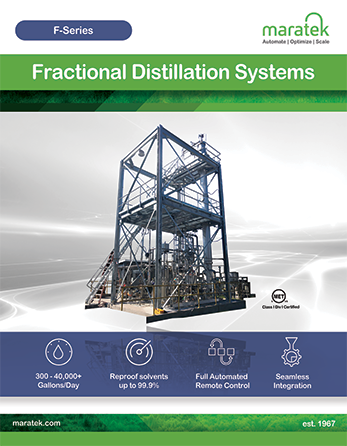

Maratek's uniquely designed fractional distillation units for automated fractional distillation and dewatering will help your business create a more efficient and cost-effective production process by reducing both solvent and operation costs. Maratek’s fractional distillation equipment is available in many standard ranges from 1-500+ gallons per hour of throughput. Maratek can also custom build, engineer and manufacture sizes above this capacity or any sort of complex mixtures that our clients are looking to separate. Our systems can be used within a variety of industries including pharmaceuticals, automotive, battery manufacturing, aerospace, and more. With over 50 years of engineering experience, Maratek can tackle any project, no matter the complexity.

Separation of any Solvent Mixture, no Matter the Complexity

Reduce Solvent & Waste Disposal Costs

Improve Solvent Purity and Effectiveness

Scale Your Operations: Process 1-500+ Gallons/Hour with 24/7 Reliability

Continuous Fully Automatic Operation

How Our Advanced Technology Works: The Science Behind 99.9% Pure Recovery

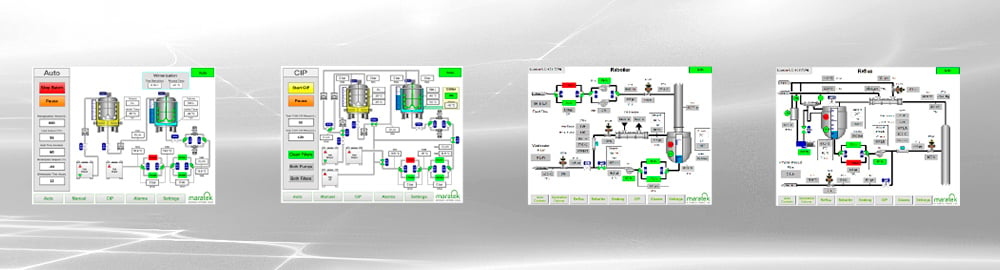

Maratek’s distillation systems are continuous, fully automated processes ensuring continuous processing of the feed and the consequent collection and removal of the distillate (top) and the bottom products, respectively. They are equipped with state-of-the-art instruments and are fully customizable for continuous and reliable process monitoring to ensure operator and plant safety.

Fractional units are primarily used to obtain purified solvents through liquid-liquid separation that can be used in other manufacturing processes. They can either be designed as stand-alone systems or be integrated with Maratek’s Continuous Solvent Recycling Systems.

The trays/packing inside the fractional column allow the vapor rising up the column to reach vapor-liquid equilibrium with the liquid flowing downwards. This process helps separate the feed entering the column into solvent-rich and solvent-lean streams based on the relative volatility of the feed components. The solvent-rich stream is collected as the distillate at the top of the column while the solvent-lean stream (with traces of solvent, if any) is collected/removed from the bottom.

To improve process efficiency and increase the purity of the solvent, boil-up and reflux streams are often introduced by recirculating vapor (by heating a part of the solvent-lean liquid) at the bottom and a portion of the condensed (solvent-rich) liquid at the top of the column.

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi non commodo mauris.

Solvent Recycling: What is Fractional Distillation?

Why is fractional distillation so important and how can you save your business money with this technology?

Learn More

3 Major Benefits of Fractional Distillation

Not sure about the benefits of fractional distillation? Check out this blog to identify the benefits.

Learn More

What is the Purity of Recycled Solvents?

Check out how you can find the right equipment for you depending on your solvent purity requirements.

Learn More

Fractional Distillation Brochure

Do you need to separate complex fluid mixtures or recycle your solvent waste to a high purity? Then read this brochure to learn more about Maratek's fractional distillation solutions.

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi non commodo mauris.

Case Study - Fractional Distillation Column in Medical Facility

Stay updated: view this case study about an installation in a medical facility, to learn more about Maratek's goal for fractional distillation.

Learn More

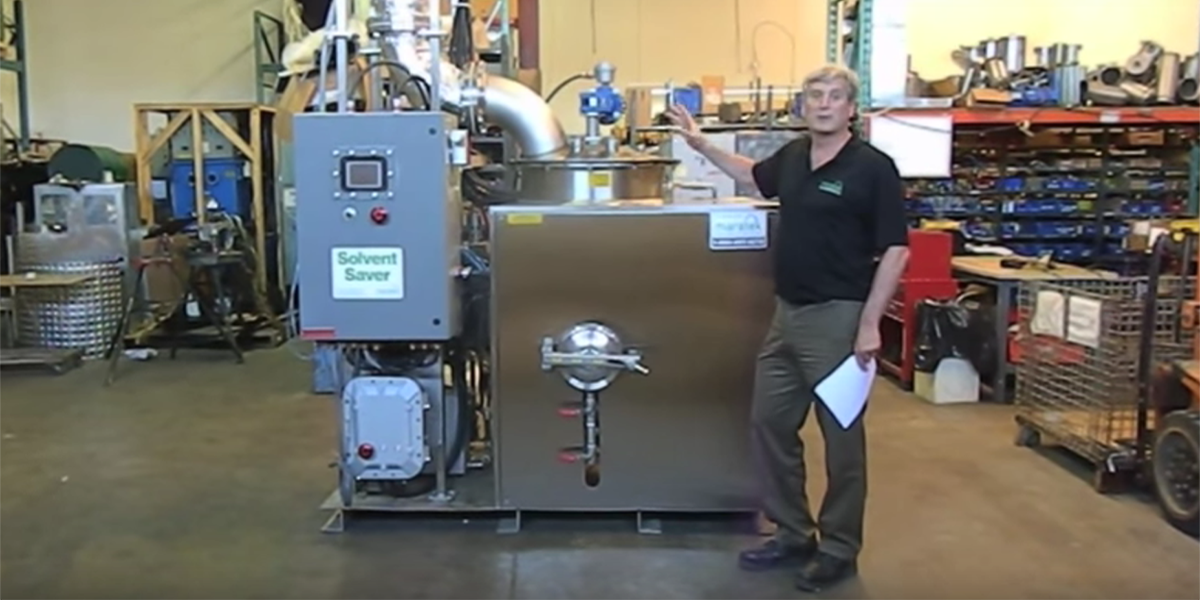

Fractional Distillation Equipment for Pharmaceutical Client

Maratek provided this pharmaceutical company with a solution for their application with custom fractional distillation equipment.

Learn More