Project Execution

From Application to Expertly Implemented Solution

Our goal at Maratek is to develop comprehensive solutions for each unique application that our clients present.

Our specialized team of engineers will work through your requirements and specifications to develop simulations, renders, PFD, P&ID, general arrangement, vessel drawings, equipment specification sheets, and any other assets needed to successfully execute your project.

Maratek's sales team, engineers, and technicians will effectively manage each stage and communicate with you throughout the entire process. Starting from the initial inquiry to development, fabrication, installation, training your team, completed commissioning and successful operation.

With over 50 years of experience, Maratek is a trusted leader in solvent recovery and recycling equipment manufacturing worldwide. You can rest assured that your project will be handled by a capable team.

Maratek has reliably served a variety of industries including pharmaceuticals, automotive, aerospace, paint, printing, cabinetry, and more. Demonstrating our knowledge and experience in executing projects within many different industrial manufacturing settings.

If you want to learn more about Maratek's engineering solutions and project execution capabilities, contact us today.

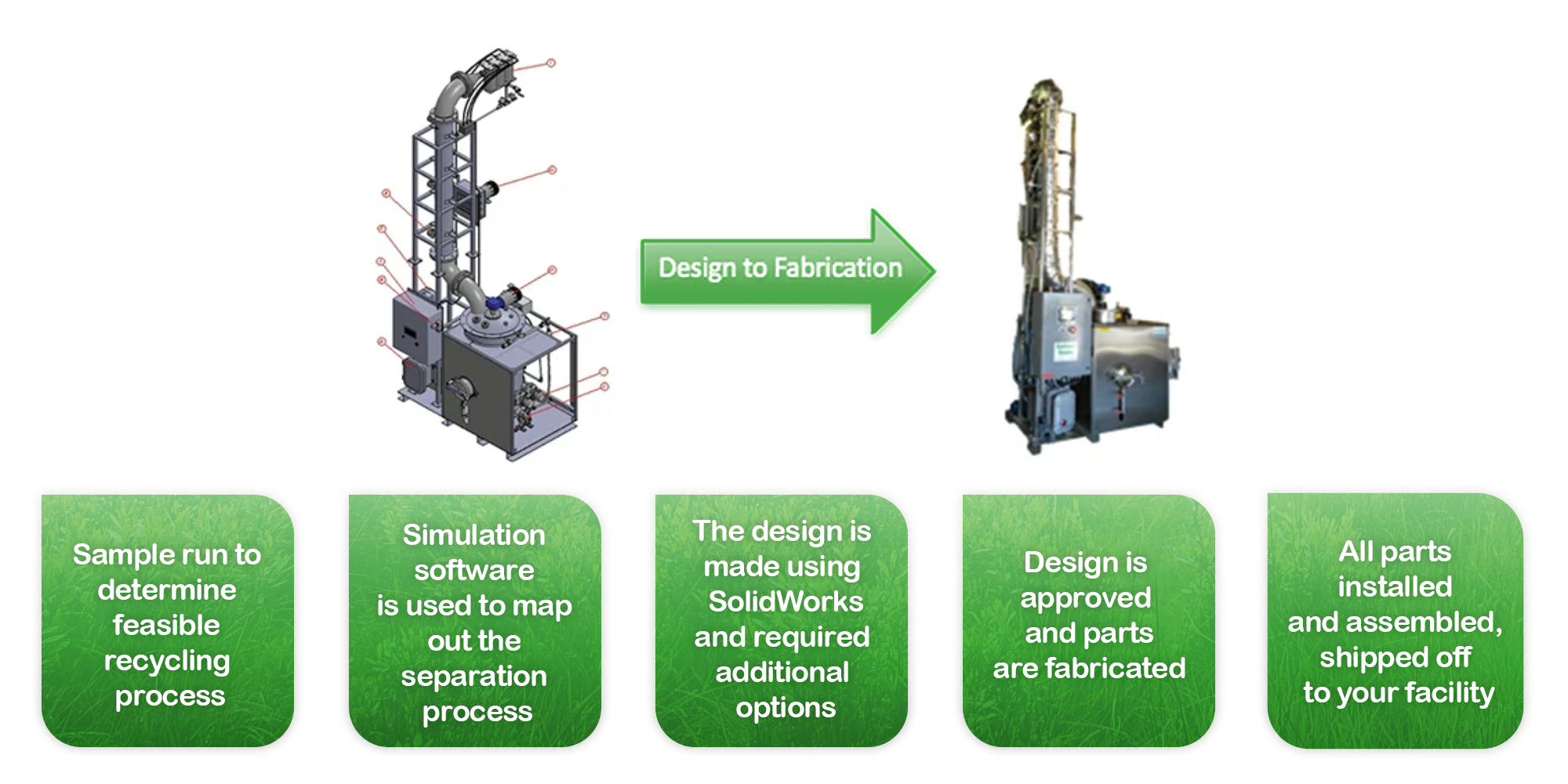

Project Execution Process

-

In-depth Project Study: The client application and requirements are reviewed and assessed through a comprehensive study.

-

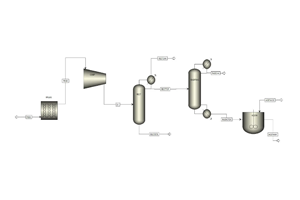

Process Simulation: Using Aspen HYSYS, our chemical engineers will test and determine the optimal chemical process for the application.

-

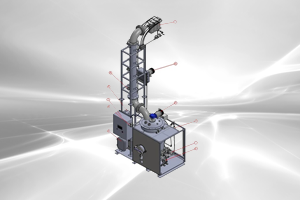

Mechanical Design & Renders: Drawings and SolidWorks 3D models are produced to visualize and aid in design validation.

-

Fabrication & Assembly: Required parts are fabricated and assembled in-house by our talented production team.

-

Integration with Project Site: The system is delivered to the client's site and integrated with their existing industrial process.

-

Onsite Commissioning with Lifetime Support: Our team of technicians will provide onsite training and start up optimization, as well as ongoing support to ensure client success.

Engineering & Consulting Services

Custom equipment engineering

Plant engineering, layouts & design

Project management

Safety consulting

Building & room design

Product optimization

Explosion proof safety

Compliance verification

Equipment training & education

Utility optimization & energy reduction

Automated sample collection

R&D agreements and engineering contracts

Intellectual property agreements & sharing

Engineered compliance certification

Data logging and tracking

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi non commodo mauris.

Solvent Recycling: Do You Need a Custom Engineering Solution?

Many waste streams require tailored solutions. Built-to-order and custom engineering can address your needs.

Learn More

Enhancing Industrial Production with Maratek's Engineering Services

Using technology, Maratek's engineers craft process simulations, renders, and designs to help industrial manufactures.

Learn More

Custom Solvent Recycling Equipment at Maratek Environmental

Maratek offers simulation, design, fabrication, manufacturing, testing and set-up with our team of engineers.

Learn More

Success Stories: Real Results from Industry Leaders

The Solvent Saver 300 system Maratek installed here at Colorado Printing is working extremely well. It has lived up to every Maratek claim. We had tried another system that was nothing but headache after headache. We are pleased the Maratek Solvent Saver was able to help us reclaim our waste solvents.

Steve Brewer

Colorado Printing

I am pleased with Maratek's automatic recycling unit and service department. They have enabled us to clean up our contaminated solvent waste so that we can reuse it on-site.

Pro Form Products Ltd.

The Maratek Solvent Saver was installed just over 3 years ago and I can say it has lived up to its claims of being able to provide quality recovered solvent for reuse on our Heidelberg sheetfed presses. We had looked at other systems but the flexibility, small space requirements, and being able to use our current solvent without switching made the Maratek system our final choice. We feel we made the right decision. Lake Country Press believes in doing its part in helping our environment, the Maratek Solvent Saver definitely plays a big part in our environmental and cost saving initiatives.

Lake Country Press

We have had the Maratek Solvent Saver for several years now and without a doubt it helped us achieve and maintain lower waste generator status and make our waste volume more manageable. I allow tours for Maratek because I am proud of what it does for us and feel everyone that creates solvent waste should have a Maratek System.

Standard Printing Company

Maratek's unit has worked really well. We have been using it to recycle toluene from road paints, but most surprising of all - we can't believe how quiet it is.

City of Burnaby

We have had very few issues with our recycling unit. The installation and on-site setup was simple and fast.

Auria Solutions