Solvent Saver FLEXO Video

Unlock cost savings and sustainability with Maratek’s Solvent Saver FLEXO 200 and 500 solvent recovery and recycling systems – the perfect fusion of efficiency and environmental responsibility.

In flexographic printing, solvents like n-Propanol and Propyl Acetate are essential for cleaning equipment, often blending with nitrocellulose-laden inks that pose combustion risks. Maratek’s expertly designed equipment safely recovers these solvents for reuse, slashing waste disposal costs while prioritizing safety and performance.

With the FLEXO series, you can recycle up to 95% of your used flexographic solvents. These advanced systems process solvent waste automatically, requiring minimal operator effort, so you can focus on what matters most – your production.

Maratek’s FLEXO units deliver efficient, cost-effective recycling of your waste solvent streams, seamlessly integrating into your printing workflow. Designed for simplicity and reliability, they empower your operation to reduce costs, enhance sustainability, and maintain peak productivity with ease.

Click the images above to download the FLEXO 200 or 500 brochures.

Maratek’s FLEXO 200 and FLEXO 500 solvent recovery systems deliver powerhouse performance, reclaiming up to 200 gallons and 500 gallons per day, respectively. To ensure the perfect fit for your needs, our expert team analyzes your waste stream characteristics, matching you with the ideal solvent recycling solution. Thanks to cutting-edge automation, these systems operate nearly hands-free, maximizing efficiency with minimal oversight.

These recovery rates are benchmarked using pure acetone as the reference chemical, free of contaminants. Unlike other systems, FLEXO units eliminate the need for bags and boast an array of advanced features, including internal mixers and scrapers. These components expertly manage waste buildup, ensuring smooth handling and discharge of even the most viscous residues.

Safety and precision are at the core of every FLEXO system. Equipped with glycol heating and high vacuum technology, these units maintain low operating temperatures to safely process nitrocellulose-laden waste without risking combustion. For added protection, a water quench feature is standard, enhancing operational security.

Crafted entirely from durable 304 stainless steel, both the FLEXO 200 and 500 are built to last. These water-cooled systems require a chilling water source – conveniently available through Maratek – to optimize performance.

Versatility defines the FLEXO line. With configurable heating and condensing mediums, these solvent recycling units can be customized to tackle the unique demands of your waste stream. By selecting the right options, you’ll unlock a tailored, cost-effective solution that boosts sustainability, slashes waste disposal costs, and seamlessly integrates into your flexographic printing process.

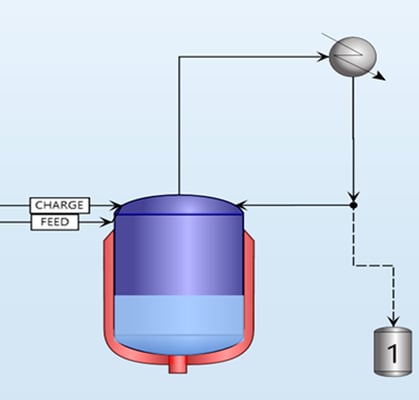

Maratek’s FLEXO 200 and 500 models separate solvents using the proven process of distillation, as described below.

.png?width=347&height=491&name=Maratek%20Case%20Study%20Columbia%20Packaging%20Group%20(347%20x%20491%20px).png)

See how Columbia Packaging Group reduced solvent waste and operating costs using Maratek’s Flexo solvent recovery system.

This case study highlights how high-volume flexo printers can recover up to 90% of solvents while improving safety and sustainability.

Read the full case study to learn how solvent recovery delivered measurable savings without upfront capital investment.

In flexographic printing operations, solvent recycling is a critical driver of cost control, regulatory compliance, and sustainability performance. Yet many facilities operate solvent recovery systems without clearly measuring how well they are performing or how much value they deliver.

Flexographic printing (also referred to as flexo) is a versatile printing technique widely used for packaging materials, labels, and other substrates. This method has grown significantly in popularity due to its adaptability, cost-efficiency, and high-speed production capabilities.

The flexographic printing industry is one of the newer industries introduced in the 21st Century. Flexographic printing was developed through technological advancements to improve the quality of manufacturing.

Global: (905) 857-2738

1-800-667-6272

sales@maratek.com

Canada

39 Nixon Road, Bolton, Ontario L7E 1K1, Canada

United States

250 Monroe Ave. NW, Suite 400, Grand Rapids, MI, 49503

Germany

Friedrichstr. 155, 10117 Berlin, Berlin Germany

Spain

Avda. de Europa 26 ATICA 5, 2ª planta, 28224 Pozuelo de Alarcón, Madrid, Spain

UK

207 Regent Street, Suite 8, Third Floor, W1B 3HH London, United Kingdom