Solvent Saver Printing (SSP) Recycling Equipment

Maratek’s Solvent Saver Printing units will help you reduce the amount of waste you produce

Substantial cost savings that can be passed on to your customers and reduced VOC generator status that makes your environmentally responsible operation attractive to clients and investors.

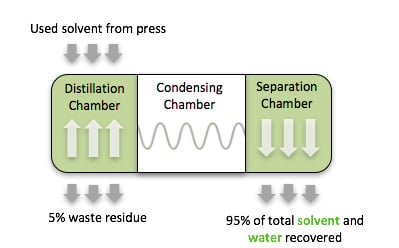

One drum of virgin solvent on the press results in two drums of waste that cost over $300 to dispose of.

By recycling that solvent, you end up with nearly all of the solvent to reuse and less than $20 of waste to ship.

That’s a 95% reduction in hauling costs and a lot less new solvent to buy!

The Maratek SSP solvent recycler models can be designed to handle many different outputs. Operation is fully automatic via a PLC controller with a color LCD touchscreen interface.

With the Maratek SSP models (8, 16, 32, 75, 110), you can run one drum of solvent through your press over 10 times before you have one drum of waste to ship.

See How Easy It Is to Save Thousands on Solvent Costs"

The Maratek Solvent Saver Printing (SSP) models use a multi-stage vacuum distillation process that separates solvent into its components at lower-than-boiling point temperatures.

Any waste residues are self contained within the unit, distilled water can usually be sent down the drain, and the reclaimed solvent is ready to go back on the press. The SSP is an off-press automated machine that, once installed, needs very little attention.

Switching out drums and using our touch-sensitive control screen is virtually all the labour that is required. It has a small footprint and because it operates at low temperatures, its explosion-proof design is safe for installation in the pressroom in most cases.

Solvent Saver SSP Options

- Oil Cooling

- Cellular Access

- Container Sensors

- Dual Dose Fill and Empty

- Allen Bradley PLC

- Purge Box

- Inspection Glasses

- Post Solvent Blending

- Activated Carbon Filter

- Water Chiller

See Real Customer Success Stories: How They Reduced Solvent Costs by 95%