How Can Maratek’s Engineering Services Enhance Industrial Production Efficiency?

The industrial sector is in a perpetual state of evolution, compelling manufacturers to consistently fine-tune their production processes for heightened efficiency, cost reduction, and enhanced environmental sustainability.

The industrial sector is in a perpetual state of evolution, compelling manufacturers to consistently fine-tune their production processes for heightened efficiency, cost reduction, and enhanced environmental sustainability.

In this dynamic landscape, Maratek stands as a premier provider of professional engineering services, delivering innovative solutions to confront these challenges head-on.

Harnessing cutting-edge technology such as Aspen HYSYS and SolidWorks, Maratek's team of adept engineers crafts process simulations, renders, and designs, empowering industrial manufacturers to surmount intricate hurdles and optimize their operations.

The Power of Process Simulations with Aspen HYSYS

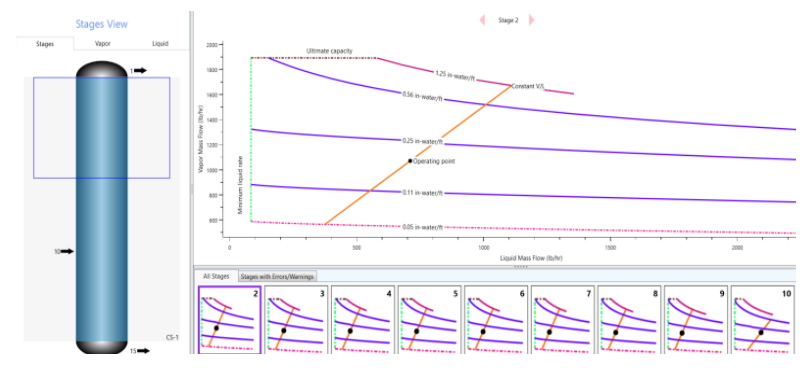

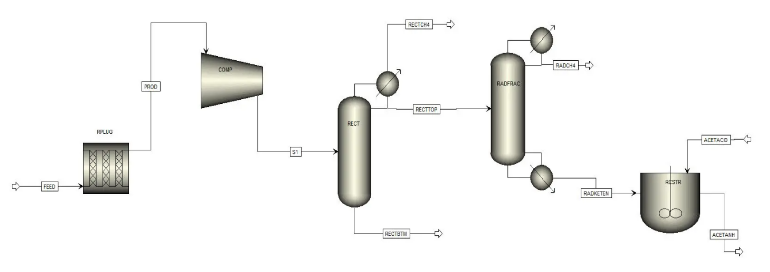

Process simulations serve as a pivotal tool in the conception, refinement, and scrutiny of industrial processes. These simulations emulate real-world process dynamics, facilitating experimentation to fine-tune a system's operational parameters.

Virtual experiments conducted through simulation models offer a means to explore diverse scenarios swiftly, safely, and cost-effectively, in stark contrast to real-world testing. A myriad of simulation tools is available to optimize design studies, engineering analyses, debottlenecking studies, equipment sizing, process simulation, dynamic simulation, and digital twins.

Notable examples include Advanced Simulation Library (ASL), ASCEND, Aspen HYSYS, Aspen Plus, and CHEMCAD. Maratek's engineering team capitalizes on Aspen HYSYS to simulate a broad spectrum of applications, ranging from batch distillation to intricate fractional distillation processes.

Advantages of Simulation

- Process and Control Simulation: Testing and training on novel processes, designs, and parameters curtail commissioning time during startup and facilitate sensitivity analysis under extreme conditions.

- Enhanced Safety: Mitigate risks before commissioning by enabling users to acquaint themselves with, optimize, and bolster operational competencies prior to offshore deployment.

- Comprehensive Scenario Testing: Mitigate or eliminate downtime by enabling operators to assess proposed process modifications and operational changes, while also identifying issues within the simulation rather than in the plant, reducing maintenance expenses.

- Improved Operator Training: A virtual simulation mirroring plant operations enhances operator proficiency via secure, hands-on, offline training and skill honing.

- Lifecycle Simulation: Predict the ramifications of design alterations, parameter adjustments, flow rate changes, new commissioning, and validate optimization prior to real-world implementation.

Cutting-Edge Renders and Designs with SolidWorks

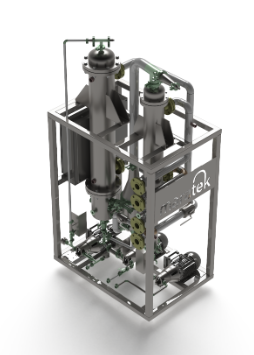

SolidWorks, a computer-aided design (CAD) software, plays a pivotal role in the development process. Maratek's engineers employ SolidWorks to transform concepts into photorealistic renders, affording a visual preview of the final product before physical production commences. SolidWorks excels in delivering precise prototyping and modeling of various components, equipment, and systems.

SolidWorks, a computer-aided design (CAD) software, plays a pivotal role in the development process. Maratek's engineers employ SolidWorks to transform concepts into photorealistic renders, affording a visual preview of the final product before physical production commences. SolidWorks excels in delivering precise prototyping and modeling of various components, equipment, and systems.

Our engineers forge 3D models that faithfully replicate the intricacies of proposed industrial equipment designs. These models aid in design validation, optimization, and the early detection of potential flaws, thereby economizing time and resources.

Solving Complex Industrial Challenges

Industrial manufacturers grapple with a myriad of challenges, spanning regulatory compliance, environmental sustainability, operational efficiency, and cost-effectiveness.

Maratek's professional engineering services yield tailored solutions that elevate production operations. Amidst mounting pressure to diminish environmental footprints and adhere to stringent regulations, our team specializes in crafting processes that minimize waste generation, optimize resource utilization, and align with environmental regulatory standards.

By harnessing process simulations, Maratek assists manufacturers in identifying eco-friendly alternatives and implementing sustainable practices, fostering a greener industry through innovative technology.

Operational efficiency reigns supreme in the competitive industrial landscape. Maratek's process simulations empower companies to unearth inefficiencies, streamline operations, and optimize production schedules. Through comprehensive scenario analyses, manufacturers can make informed decisions, culminating in reduced operational expenditures, heightened throughput, and amplified overall efficiency.

Thorough design and meticulous testing are prerequisites before implementing a new system. Maratek's proficiency in SolidWorks expedites solution development cycles by crafting precise prototypes and validating designs pre-production. This not only trims development timelines but also ensures that systems are primed for peak performance and reliability.

Every industrial operation is unique, replete with its distinct challenges. At Maratek, we excel in furnishing clients with bespoke solutions, aligning with specific business requisites, be it designing specialized equipment or optimizing intricate manufacturing processes.

Innovation and efficiency stand as the pillars of success in the industrial landscape. Through process simulations, visual renders, and tailored engineering expertise, Maratek empowers manufacturers to make judicious choices, curtail costs, and elevate their overall business operations.

Maratek remains a steadfast partner, endowing the requisite expertise to navigate complex quandaries and catapult manufacturers to new pinnacles of success. Reach out to us to explore how Maratek's engineering solutions can augment your business today.