Top 4 Benefits of In-House Solvent Recycling Equipment

The high cost of solvents and the resulting waste cause unnecessary costs that can be easily saved with an effective solvent recycling system.

The high cost of solvents and the resulting waste cause unnecessary costs that can be easily saved with an effective solvent recycling system.

For a typical printer, one drum of virgin blanket wash used on the press results in about two drums of waste that can cost in excess of $300 to dispose of. By recycling that used blanket wash, you capture nearly all of the solvent to reuse with less than $20 of waste to ship.

This results in a 95% reduction of hauling and disposal costs with less new blanket wash to purchase!

There are many benefits to solvent recycling – here are our top 4!

1. Economic Benefits

Solvent recycling and recovery is designed to help your facility accomplish two major goals – reducing liquid waste disposal expenses and recycling of your liquid solvent waste such as solvent waste, alcohol waste, blanket wash, and liquid cleaning solvents – providing huge economic benefits.

With the price of solvent continuing to rise, the MaraSolve program allows you to eliminate costly increases by purchasing your own recycled solvent back. Waste disposal and solvent purchase expenses will be reduced from what you are currently paying.

Maratek also offers a Share the Savings program that allows customers to rent or lease equipment with no risk, no money down, and no capital expenses.

Based upon our experience with over 250 installed Solvent Saver Systems, the equipment typically pays for itself in less than 12-18 months!

2. Environment Benefits

Solvent recycling not only reduces your solvent purchases and waste, it also reduces your environmental impact. Solvent recycling and recovery minimizes disposal costs, fresh chemical purchases and storage costs.

When you’re finished with your solvent, it is categorized as hazardous waste. Hazardous waste is difficult to dispose of – recycling and recovering your hazardous waste eliminates the need for disposal. In addition, recycling reduces emissions and reduces the impact on surrounding communities.

3. Regulatory Compliance

The handling and disposal of hazardous waste is heavily legislated to protect the environment and Canadian residents. In Canada, all three levels of government are involved in hazardous waste legislation. The goal of hazardous waste legislation is to prevent pollution and protect the environment and human health. This is achieved through strict regulations and the implementation of green initiatives.

As a hazardous waste producer, you are subject to these strict regulations. Implementing a recycling and recovery program will reduce your production of hazardous waste while showing your support of green initiatives.

4. Enhancing Workplace Safety

Improved Safety Protocols: Solvent recycling significantly enhances workplace safety. By reducing the handling and storage of hazardous solvents, it minimizes the risk of spills and exposure to toxic substances. This creates a safer work environment and can also lead to lower insurance costs due to the reduced risk of accidents.

Employee Well-Being: Implementing solvent recycling demonstrates a commitment to employee health and safety. This not only fosters a more positive work culture but also can result in higher employee satisfaction and retention.

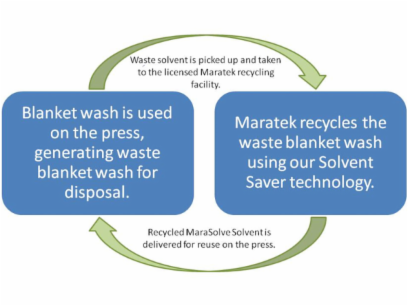

How Does Solvent Recycling and Recovery Work?

Using solvent recycling equipment from Maratek, contaminated solvents, or mixtures of chemical substances, are heated through the use of heat transfer media (thermal oil, hot water, steam) and brought to a boil. The gases resulting from this distillation process are then liquefied and cooled by condensation in the cooler.

When it comes to sensitive chemical materials, thermal decomposition can happen during distillation. In order to prevent this, and also in order to reduce energy consumption (and with this decreasing operating costs), the gentle process of vacuum distillation is used, which is performed at low pressure (vacuum).

Due to the vacuum, the boiling point of the liquids that are to be separated is reduced, as well as the possibility of foaming, is significantly reduced and the components evaporate at a much lower temperature than at normal pressure.

For over 50 years, Maratek has served a wide range of industries generating hazardous waste, such as printing and paint manufacturing. Located in Bolton, Ontario, Maratek is a leader in environmental solutions that help your business save money.

Interested in learning more about Solvent Recycling and Recovery? Contact us today!