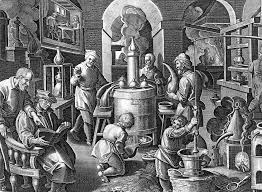

How Does Solvent Distillation Work?

Whether in the purification of water or the intricate separation of chemical compounds, distillation plays an important role when it comes to your solvent recycling and recovery needs.

But there's more to distillation than just the simple type. Fractional distillation, a more complex variant, is crucial for separating mixtures of liquids with varying boiling points. Before we get into that, however, let's first take a look at how distillation works.How Distillation Works

We're generally familiar with how distilled water is produced. The water is heated, and the steam or water vapor is conducted away in a tube. If the tube is looped downward and cooling is applied below the hump, the vapor is condensed and distilled water obtained. This is called "simple" distillation, i.e., removing a volatile substance (water) from non-volatile substances (lime, impurities, etc.).

"Fractional" distillation on the other hand is a different type of distillation used to separate mixtures of two liquids with different boiling points, such as a mixture of alcohol and water.

Wikipedia defines fractional distillation as "the separation of a mixture into its component parts, or fractions, such as in separating chemical compounds by their boiling point by heating them to a temperature at which one or more fractions of the compound will vaporize. It is a special type of distillation. Generally the component parts boil at less than 25 °C from each other under a pressure of one atmosphere. If the difference in boiling points is greater than 25 °C, a simple distillation is used."

Let's take Ethyl Alcohol as an example. A mix of 4% Ethyl Alcohol and 96% water boils at approximately 173° F, while water boils at 212° F. A mixture of the two liquids will boil at a temperatures between 173° and 212°, depending on the ratio of alcohol to water.

By bringing about a controlled series of successive sequences of ... re-evaporation, condensation, re-evaporation and re-condensation, each re-condensation from the previous vapor state achieves a higher alcohol concentration. This is because the alcohol in the vapor is at a higher concentration than was the concentration in the liquid mixture from which it was vaporized.

Solvent Distillation

The solvent distillation equipment we use at Maratek, includes a tank in which the solvent waste is deposited, a heating system for turning the liquid part of the waste into vapor and a condenser to cool the vapor back into a liquid. The general process consists of boiling a mixture in a closed system and condensing the vapors back into a liquid, and disposing of the waste.

For example, consider a mixture of solvents and resins left over from a manufacturing process. A Maratek solvent distillation unit would heat the mixture to boil off the solvent, leaving the resins behind in the boiling tank and can be disposed of as waste. The solvent vapors would then re-condense in a separate area and return to their liquid - near virgin and clean state, ready to be reused.

The principles of distillation are fundamentally the same with the use of solvent recovery equipment. Methods of heating the solvent include steam, direct heat (using an electric heating element or heat plate) and indirect heat (where an oil bath surrounding the tank is heated by direct electric heat). Indirect heat is usually the preferred approach because the heating is more uniform.

The condenser is usually a series of looped copper or stainless steel coils (resembling a car radiator) that are cooled by a built-in fan or surrounded by water or coolant to chill the vapor back into a liquid. Cooling by air is less expensive than cooling by water or coolant, and is adequate for small, batch-type solvent recycling machines.

Water cooled condensers may be necessary for applications where the condensing temperature is particularly low, or the environment of the facility is unusually hot. The water cooled condenser will then be more efficient.

Maratek Manufactures a Full Range Of Solvent Distillation Systems

We can help you determine your specific solvent distillation recycling and recovery needs. There are no “one-size-fits-all” solutions to your solvent waste management concerns.

We will help you determine the needs of your business so you can buy the right equipment you need. We will not only give you a “greener” profile, but it will also pay for itself in time, saving you money on solvent purchasing and disposal costs.

We specialize in solvent recycling and solvent recovery processes using our world class and award winning solvent distillation equipment which we manufacture, sell and support to businesses around the world.

Maratek manufactures solvent equipment and has proudly served industrial manufacturers who produce hazardous chemical waste and solvent waste such as printing, photofinishing, silver and paint related manufacturers for over 40 years.

Interested in learning more? Contact our team today.