How Do Column Structure and Reflux Principles Shape the Science of Fractional Distillation?

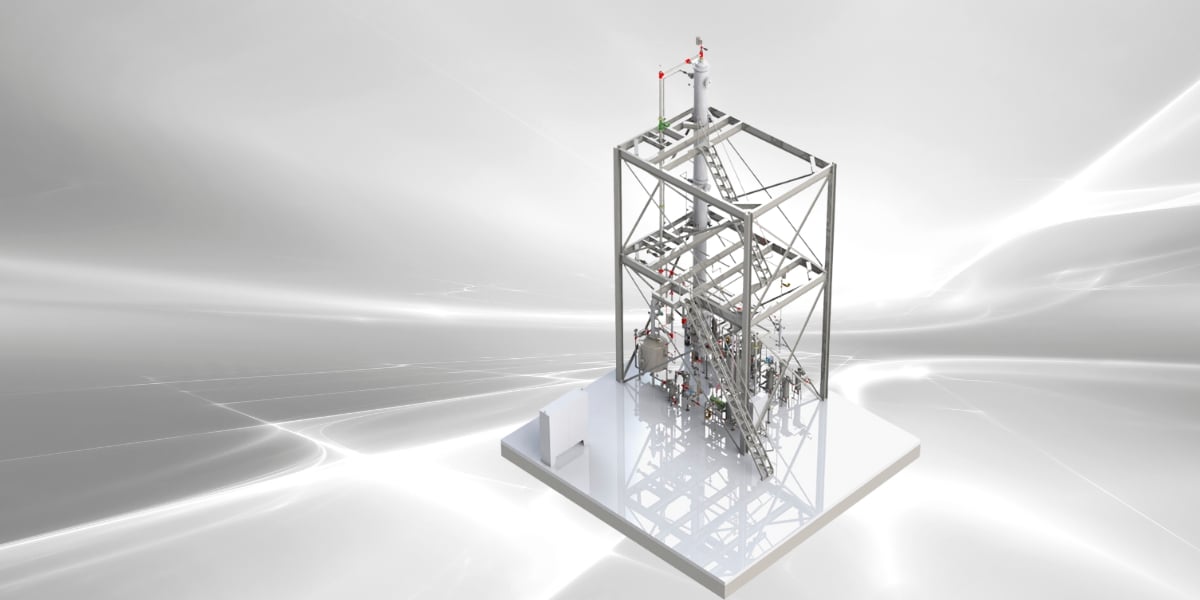

Fractional distillation is a highly efficient method used in various industrial processes, such as product refinement and waste recovery, to yield high-purity products. In this blog post, we will explore the structure of a fractional distillation column and delve into the science of reflux.

Fractional distillation is a highly efficient method used in various industrial processes, such as product refinement and waste recovery, to yield high-purity products. In this blog post, we will explore the structure of a fractional distillation column and delve into the science of reflux.

Tray Column Structure

Each tray within the distillation column facilitates interaction between gases and liquids, achieving equilibrium between them. As liquid enters and comes into contact with the gas on a given tray, both phases undergo compositional changes.

The hotter vapor phase heats the incoming liquid, causing lighter components to vaporize, leaving the tray in the vapor phase. The cooling effect of the downward-flowing liquid phase causes the heavier components in the vapor to condense and exit the column with the liquid phase.

Types of Trays

Different types of trays are used in fractional distillation columns:

- Sieve Trays

- Bubble Cap Trays

- Valve Trays

- Proprietary Trays

Packed Column Structure

A packed distillation column comprises a cylindrical vessel filled with packing material. This packing material enhances the surface area for contact between two fluids (liquid-liquid and gas-liquid), promoting efficient mass transfer.

One fluid forms a film over the packing's surface, while the other flows through the remaining vessel volume. The fluids flow countercurrently (in opposite directions) to maximize efficiency. The choice of packing material depends on its ability to provide a large surface area for mass transfer.

Types of Packing

Two main types of packing are used in packed distillation columns:

Random Packing: This type employs randomly distributed small packing materials, typically made of plastic or metal. Examples include raschig rings, lessing rings, pall rings, berl saddles, and intalox saddles.

Structured Packing: This organized packing directs liquid into specific shapes. It utilizes discs made of materials like metal, plastic, or porcelain, with internal structures arranged in various honeycomb shapes.

Understanding Reflux

Reflux is a crucial concept in fractional distillation, involving the process of returning a fraction of the condensate (the liquid obtained from condensing the overhead vapor of the lightest component) to the top of the column. This enhances the purity of the final product.

Reflux Ratio

The reflux ratio (Rd) is the ratio of the liquid fraction returned to the column (L) to the liquid fraction recovered as distillate (D). It is calculated as Rd = L/D.

Total Reflux

Total reflux is an operating condition where overhead vapors are condensed and returned to the column without any distillate being recovered. This allows vapor and liquid interaction on each tray column with no products removed. It is calculated as (D = 0, Rd = L/D = ∞).

However, running under total reflux increases operating expenses due to higher heat duties.

Minimum Reflux Ratio

The minimum reflux ratio (Rmin) is the lowest ratio at which separation can be achieved, albeit requiring an infinite number of theoretical plates. As the reflux ratio increases, the number of theoretical plates needed decreases, leading to higher capital expenditure (CapEx) but lower operating expenditure (OpEx) due to reduced reboiler and condenser heat duties.

Optimum Reflux Ratio

The optimum reflux ratio (Ro) is determined based on the total capital and operating costs of the distillation column. It represents the point where overall costs are minimized by optimizing both capital costs (dependent on the number of theoretical plates) and operating costs (dependent on the reflux ratio and heat duties).

At Maratek, our team of skilled engineers can assess your waste stream and provide a tailored fractional distillation solution to meet your specific needs. We take pride in delivering highly customizable designs that align with your requirements, including Process Flow Diagrams (PFD), Piping and Instrumentation Diagrams (P&ID), General Arrangement drawings, Vessel Drawings, and Equipment Specification sheets.

Want to learn more? Request a quote today.