What Are Aerogels and What is Their Application for Solvents?

Aerogels represent an exciting scientific advancement, showcasing remarkable properties that hold substantial promise across a wide range of applications in the solvent industry.

Aerogels represent an exciting scientific advancement, showcasing remarkable properties that hold substantial promise across a wide range of applications in the solvent industry.

As new materials and synthesis methods continue to emerge, the diversity of aerogels available has expanded. This blog post delves into the science of aerogel classification, properties, applications, and synthesis.

Aerogel Classification

In the paper "Aerogels for Waterborne Pollutants Purification" by Moheman et al., several classifications of aerogels are described, including those based on appearance, production, microstructures, or chemical composition. By production method, aerogels can be categorized as aerogel, hydrogel, cryogel, or xerogel. Microstructure-based classifications involve microporous, mesoporous, or mixed porous aerogels.

Regarding chemical composition, aerogels fall into three groups:

- organic;

- inorganic;

- and composite.

Inorganic aerogels originate from inorganic materials like metal salts, organic aerogels from organic materials, and composite aerogels result from a blend of both inorganic and organic compounds.

Aerogel Properties

The paper "Composites of Silica Aerogels with Organics: A Review of Synthesis and Mechanical Properties" by Lee et al. discusses key properties of aerogels. These materials exhibit extremely low density, low thermal conductivity, high porosity, and low dielectric properties.

Silica aerogels, while exceptional, can be sensitive to low-pressure environments and are relatively fragile. They possess a vast surface area due to the intricate three-dimensional network of silica particles comprising them.

Lee et al. continue to list various applications for aerogels. They find use in insulation systems, environmental cleanup, heat storage, windows, paint thickening, aeronautics, and thermal insulation. Aerogels also contribute significantly to energy conservation in industrial and domestic processes.

Aerogel Synthesis

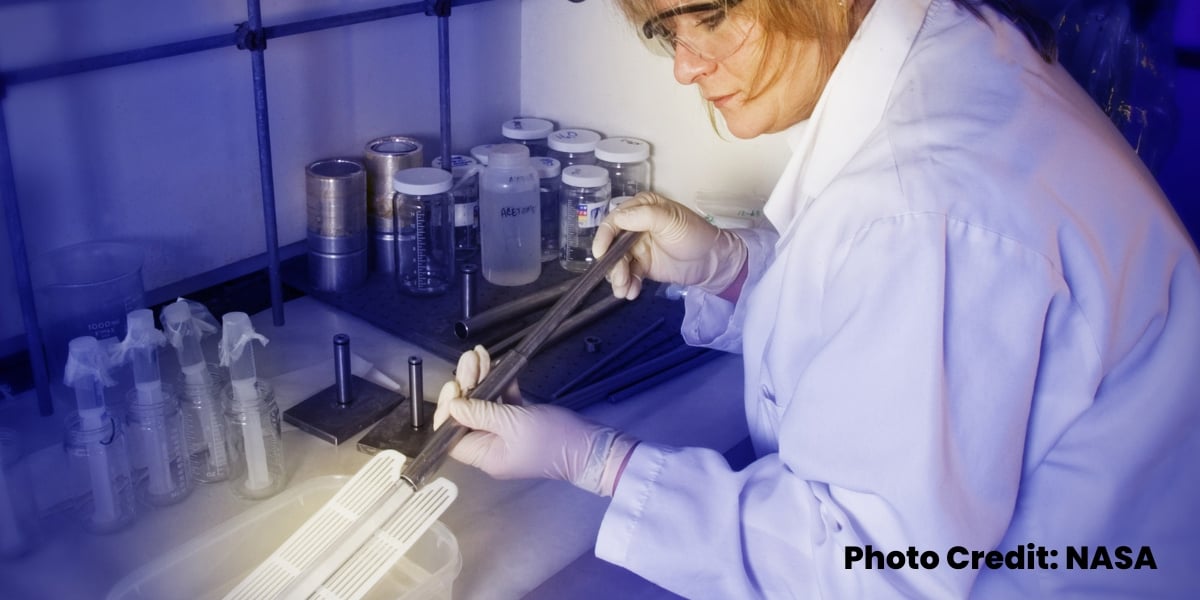

In an article by Tori Woods titled "Aerogels: Thinner, Lighter, Stronger", published by the Glenn Research Center, the process of aerogel synthesis is elucidated. Silica-based aerogels are commonly produced through this process.

It commences with the creation of a gel by mixing silica and a solvent. Supercritical fluid extraction occurs by introducing liquid carbon dioxide into the gel. The carbon dioxide reaches the supercritical state and is then extracted, a procedure repeated several times to ensure the absence of liquid. The residue left behind post-extraction constitutes the aerogel. Silica aerogels, although lightweight and highly porous, exhibit fragility and poor heat conductivity.

Addressing fragility can involve the creation of polymer aerogels, which share characteristics with silica aerogels but offer increased strength. Another option is the production of polymer-reinforced aerogels, which gain significantly in strength, thanks to an interior surface coated with polymer.

In their paper "Linear and Crosslinked Polyimide Aerogels: Synthesis and Characterization", Simón-Herrero et al. discuss the use of high-performance polymer polyimide in creating aerogels. This polymer boasts properties that make it a suitable candidate for aerogel applications. Combining polyimide and aerogels produces a highly advantageous material with numerous practical applications.

Kantor et al. outline a polyimide aerogel synthesis method employing N-methyl-2-pyrrolidone (NMP) in their paper "Heterogeneous Silica-Polyimide Aerogel-in-Aerogel Nanocomposites". NMP serves as a solvent to create the necessary polymer solution for preparing polyimide aerogels.

The Growing Demand of Polyimide Aerogels

Given the expanding applications of polyimide aerogels, there may be a growing demand for materials associated with their synthesis, including polymers and N-Methyl-2-pyrrolidone (NMP).

NMP - an excellent solvent with diverse industrial applications such as petrochemicals, pharmaceuticals, and microelectronics - offers several advantages, including a high flash point, excellent solubility, and low volatility. Additionally, NMP can be recycled, with a distillation process capable of recovering up to 95% of the waste solvent.

However, it is crucial to emphasize that NMP distillation must be conducted with care, as it can become flammable at higher temperatures, posing an explosion risk.

Maratek offers expertly designed solvent recycling units capable of handling this task, simplifying the recovery process. Contact us today to explore how we can assist you further.