Custom Solvent Recycling Equipment

Many waste streams require unique solutions. Maratek can design custom equipment to address specific recycling requirements.

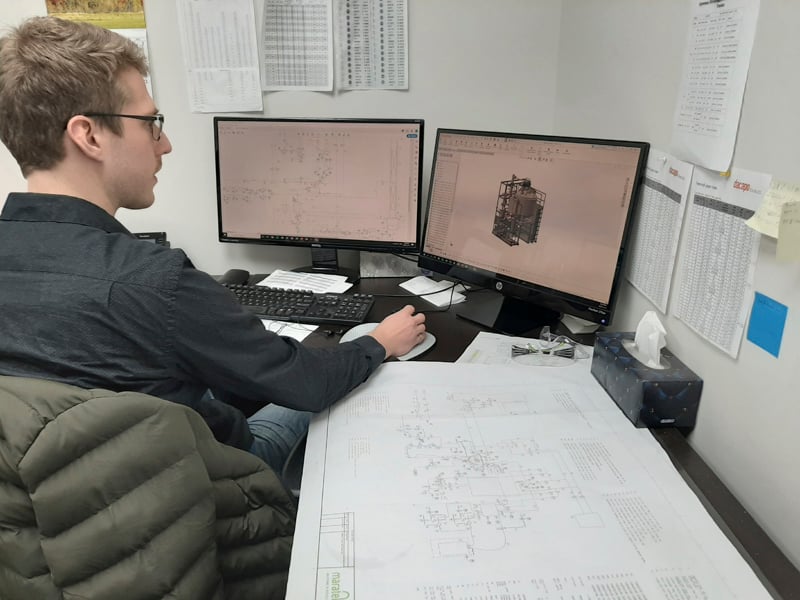

In the design of custom systems, we not only consider the actual recycling process, but also integration into the plant, ease of operation and payback. We know that the key to a successful recycling system is understanding your needs and adapting our solutions to them.

We have a department ready to design the perfect solution for you. Get a quote today or contact us with any questions you may have.