DESCRIPTION |

ASTM STANDARDS |

“TORS” EXPECTED RESULTS |

|

Gas content |

D 2440 |

0.01 % per volume |

|

Color appearance |

D 1500 |

Clear (visual) |

|

Interfacil Tension (IFT) |

D 971 |

> 30 Dynes /cm |

|

Maximum residual water |

D 1533 |

< 6 mg /kg (5 PPM Per Weight at 20 0 C) |

|

Dielectric strength |

D 877 |

> 60KV at 2 mm & 0.5 KV/sec |

|

Dissipation factor |

D 924 |

02 % tg (d) 20 0 C |

|

Neutralization value (acidity) |

D 974 |

< 0.05 mg KOH / g |

|

Suspended solids |

|

< 250 particles per 20 ml |

|

Residual gas (Air) |

ASTM – D 831 |

0.25 % per volume at 20 0 C |

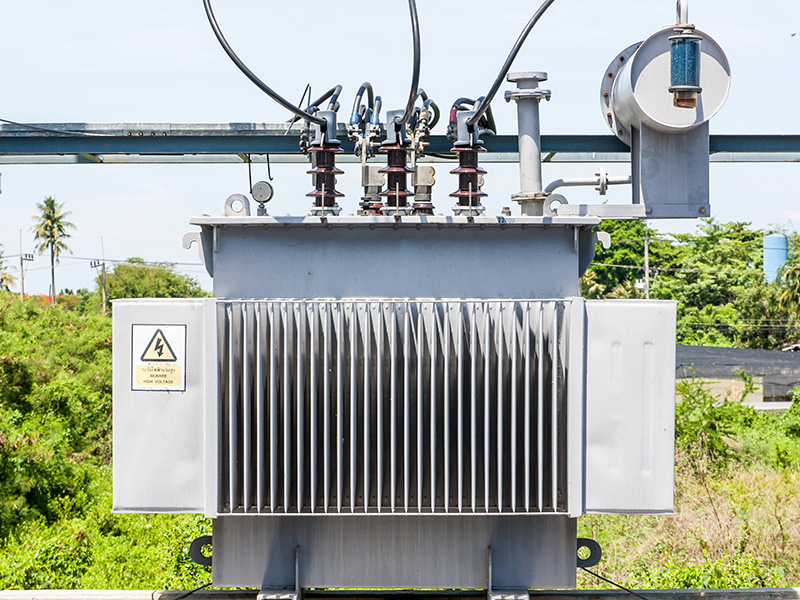

Oil Recycling & Recovery For Transformers

Transformer Oil Regeneration System (TORS)

Maratek’s TORS Transformer Oil Recycling System restores insulating oils in high-voltage transformers and switch-gears with cutting-edge technology, delivering:

-

Superior Purification: Exceeds ASTM standards for exceptional oil quality.

-

Unique Reactivation System: Continuously reactivates media without interrupting purification, ensuring uninterrupted operation.

-

Flexible Applications: Treats oils in situ with live transformers or in-plant, customized to your specifications.

-

Sustainable Efficiency: Reduces costs and environmental impact with high-purity oil recovery.

Trusted globally, Maratek’s custom-engineered TORS systems ensure rapid ROI and seamless integration.

-

Reduces water content from 100 PPM to ASTM-compliant levels.

-

Achieves high dielectric strength and low acidity for optimal performance.

Get Started: Request a free consultation today to optimize your transformer oil recycling with Maratek’s TORS solution.

The performance table below shows typical performance of a TORS System. Note that the TORS System exceeds ASTM Standards.

TORS Performance Notes: Tailored Excellence

Maratek’s TORS Transformer Oil Regeneration System delivers high-purity oil recovery with precision and efficiency. Below are key performance metrics for oils entering with 100 PPM water content, 12% air volume at 20°C, and 0.2 mg KOH/g acidity:

-

Efficient Acidity Reduction:

-

1 lb. Fullers Earth (FE) reduces acidity to 0.05 mg KOH/g for 5 gallons of oil.

-

1 lb. Activated Alumina achieves the same for 20 gallons.

-

-

High-Capacity Treatment:

-

3,000 lbs. FE treats 15,000 gallons of oil before reactivation.

-

3,000 lbs. Activated Alumina purifies 60,000 gallons to ASTM standards.

-

-

Custom Integration: TORS is tailored to your specifications, ensuring seamless integration into your production process.

These metrics showcase TORS’ ability to lower costs, extend oil life, and meet stringent industry standards with minimal environmental impact.

Optimize Your Operations: Request a free consultation today to discuss your needs and explore TORS specifications with Maratek’s experts.

Success Stories: Real Results from Industry Leaders

The Solvent Saver 300 system Maratek installed here at Colorado Printing is working extremely well. It has lived up to every Maratek claim. We had tried another system that was nothing but headache after headache. We are pleased the Maratek Solvent Saver was able to help us reclaim our waste solvents.

Steve Brewer

Colorado Printing

I am pleased with Maratek's automatic recycling unit and service department. They have enabled us to clean up our contaminated solvent waste so that we can reuse it on-site.

Pro Form Products Ltd.

The Maratek Solvent Saver was installed just over 3 years ago and I can say it has lived up to its claims of being able to provide quality recovered solvent for reuse on our Heidelberg sheetfed presses. We had looked at other systems but the flexibility, small space requirements, and being able to use our current solvent without switching made the Maratek system our final choice. We feel we made the right decision. Lake Country Press believes in doing its part in helping our environment, the Maratek Solvent Saver definitely plays a big part in our environmental and cost saving initiatives.

Lake Country Press

We have had the Maratek Solvent Saver for several years now and without a doubt it helped us achieve and maintain lower waste generator status and make our waste volume more manageable. I allow tours for Maratek because I am proud of what it does for us and feel everyone that creates solvent waste should have a Maratek System.

Standard Printing Company

Maratek's unit has worked really well. We have been using it to recycle toluene from road paints, but most surprising of all - we can't believe how quiet it is.

City of Burnaby

We have had very few issues with our recycling unit. The installation and on-site setup was simple and fast.

Auria Solutions