How Can You Get Started With In‑House Solvent Waste Recycling?

Do you use a lot of solvent?

Do you use a lot of solvent?

Do you spend a lot of money dealing with the solvent waste?

To stay competitive, you’ve got to keep costs low. But to keep environmental regulators happy and customers and investors interested, you’ve got to demonstrate “green” initiatives. What can a company do?

Try Using A Solvent Recovery Program

Did you know recovered and reclaimed solvent is virtually indistinguishable from the virgin solvent product?

That's right, recovered solvent is as good as new and can be reused in your process without any side effects.

By using a program such as our Maratek Solvent Saver, with award-winning, proven technology, you can reduce the amount of solvent you use and the amount of waste you produce.

The benefits are substantial cost savings that can be passed on to your customers and reduced VOC generator status that makes your environmentally responsible operation attractive to clients and investors.

Did You Say “Cost Savings”?

No, we said “substantial cost savings”!

One drum of virgin solvent on the printing press results in two drums of waste that cost over $300 to dispose of.

By recycling that solvent, you end up with nearly all of the solvent to reuse and less than $20 of waste to ship. That’s a 95% reduction in hauling costs and a lot less new solvent to buy!

Given those figures, the Solvent Saver could pay for itself in about 18 months.

Typical Annual Savings Based Upon Drum Usage*†

1 – 2 Drums - $ 9,200 – 18,400

3 – 5 Drums - $ 27,600 – 46,000

6 – 14 Drums - $ 55,200 – 128,800

15 – 42 Drums - $ 138,000 – 386,400

* from reduced solvent purchases and waste disposal

† based on $8/gal solvent purchase price and $3/gal waste disposal price

With the Maratek Solvent Saver Program, you can run 1 drum of solvent through your printing press over 10 times before you have 1 drum of waste to ship.

How Does It Work?

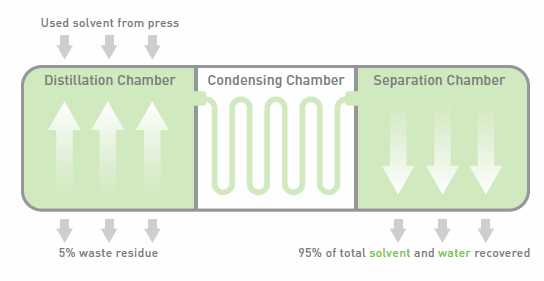

The Maratek Solvent Saver users a multi-stage distillation process that separates solvent into its components at lower-than-boiling point temperatures. Any waste residues are self contained within the unit, distilled water can be usually sent down the drain and the reclaimed solvent is ready to go back on printing press.

The Solvent Saver is an off-press automated machine that, once installed, needs very little attention. Switching out drums and using our touch-sensitive control screen is virtually all the labour required. It has a small footprint and because it operates at low temperatures, its explosion-proof design is safe for installation in the pressroom in most cases.

Trust Our Experience

Maratek has been in business for over 50 years and we continue to grow and adapt to an ever-changing printing industry. As market leaders in solvent recycling for the last 20 years, we take pride in providing our customers throughout North America with reliable, innovative, and cost saving recycling solutions.

The Maratek Solvent Saver is the proud recipient of the 2005 InterTech Award for Technological Excellence.

For more information or a free solvent waste sample payback analysis of how you can save on recycling, contact us at 1 800 667-6272 or visit our website at www.maratek.com.