Cannabis and Hemp Extraction: Is Winterization The Best Route For You?

There are many elements that form the plant profile of the cannabis and hemp plants. Cannabinoids, terpenes, flavonoids, fats, waxes, lipids, and chlorophyll all make up the plant, but they are not all needed, or wanted, in the final crude oil product.

The process of winterization uses very cold temperatures to separate the undesirables from the final product - improving its quality.

Why use the winterization process in cannabis and hemp extraction?

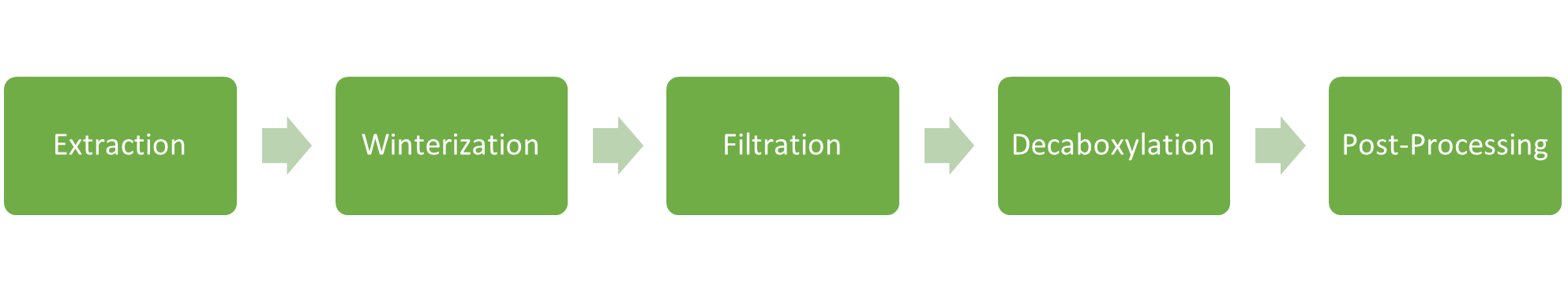

Winterization is performed after the CO2 extraction process is complete. This extraction method is performed for its ability to extract a much larger portion of the plant profile as compared to warm extraction or even solventless extraction.

This style of extraction offers an opportunity to formulate a unique and diverse experience for the final customer with a large majority of the cannabinoids, flavonoids and terpenes remaining after the chilly extraction process is complete.

Along with those unique and undesired compounds are fats, waxes and lipids in the oil as well, and these are not removed in extraction. These make the final product appear cloudy and can also have a negative effect when it is being heated. For instance, in a vape cartridge, fats would burn in the device and produce an unpleasant taste.

How does winterization improve the final product?

For a more consistent and purer product, winterization is an additional process that is used.

Winterization is often an important step before post processing techniques, like distillation, to ensure a high-quality initial input so a higher potency of THC or CBD can be extracted. In general, winterization is used to improve purity, appearance, and salability of the final product.

How does the winterization process work in cannabis and hemp extraction?

When the extraction process is complete, what remains is a peanut-butter-like material. It remains thick since the fats, waxes, lipids, and chlorophylls are in the solution. To begin the winterization process, ethanol, or another solvent, is homogenized with the extracted material. This new solution is not as thick and easier to manipulate.

Winterization uses very cold temperatures in its process - hence the fitting name. The ethanol will not freeze at these temperatures, but the low temperatures will cause the undesirables to precipitate out. The cannabis extract stays homogenized with the ethanol while the fats, waxes, and lipids clump together.

A key step in the winterization process is that temperatures remain very low, below -20°C.

After some time has passed, the undesirables will fall out of the solution and the product can be filtered to remove any further undesirable compounds that remain.

For small batches, this process can be completed by putting the extracted material into a freezer for 24-48 hours at which point you can see clumps of the fats, waxes and lipids scattered throughout the desired material. The next step is to filter these compounds out. A comprehensive filtering process ensures that all these materials are collected and removed.

From there, the mixture still needs to be decarboxylated to activate the cannabinoids, and have the ethanol removed. Then, you will be left with a final product that is ready to sell or be processed into distillate.

For the winterization process, there are multiple systems available that provide chilling and filtration. Something important to keep in mind when looking for equipment is if there are openings in the process, the material can heat up. This makes it much more difficult to separate and filter and can reduce the quality of the final product.

The key to successful winterization is the removal of fats, waxes and lipids and the creation of a clear, pure final oil for sale or further processing. Maratek’s Turnkey Winterization systems are closed loop, automated systems designed to produce the highest quality oil.

Contact us today. We would love to talk to you about how our engineers can get you started with improving the quality of your product today.