Turnkey Cryogenic Ethanol Extraction Line Video

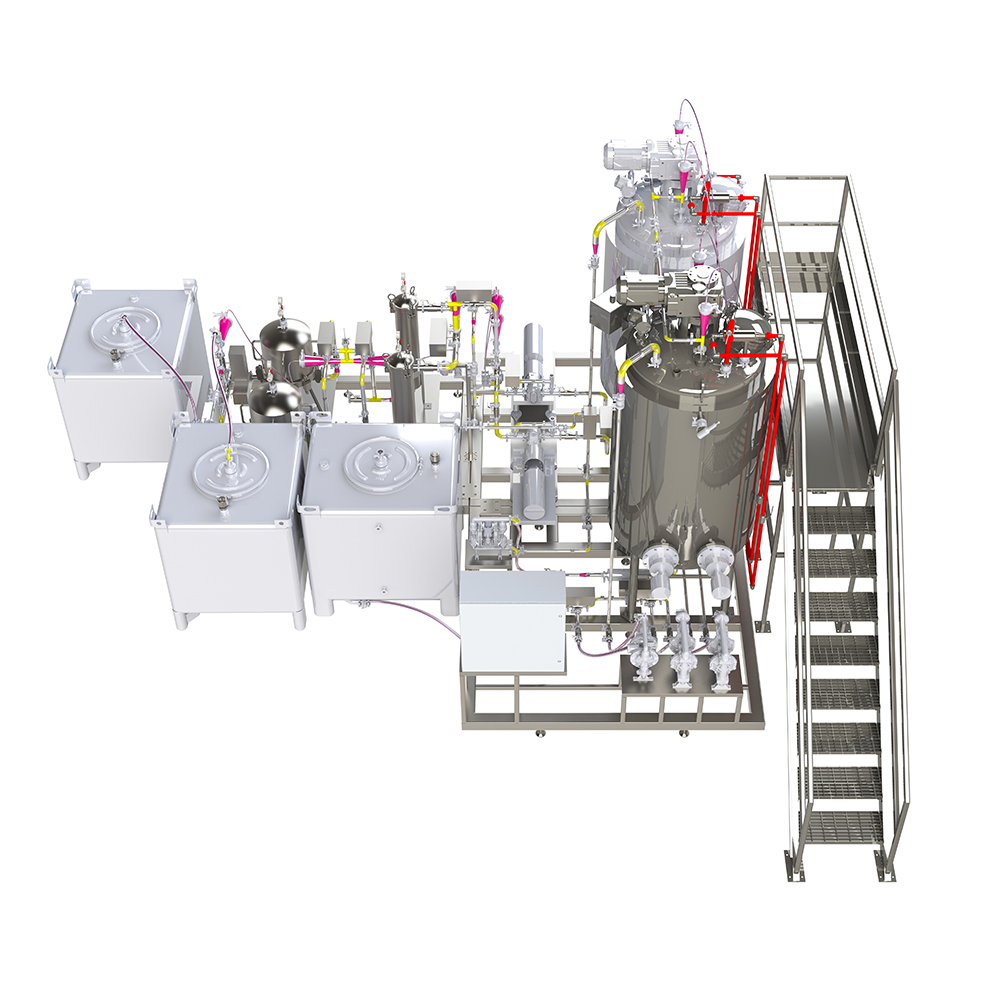

Maratek’s Turnkey Cannabis Oil Extraction Facilities are designed to meet the growing demand for industrial scaled facilities looking to produce high-quality CBD and other cannabis oils. With over 50 years of engineering experience, Maratek has brought its vast knowledge to the Cannabis & Hemp industry to design and manufacture fully automated, GMP compliant, extraction facilities, at scale.

Most commonly, these facilities utilize either warm or cryogenic ethanol extraction in both single and multiple wash configurations. We automate the entire process from your infeed cryogenic ethanol extractor, solvent recovery, filtration, decarboxylation and post-processing to your final desired full-spectrum cannabis oil, whether that be an isolate or distillate.

As a cannabis oil extraction industry leader, we provide fully designed, safe, engineered and optimized turnkey facilities in an automated closed-loop process from biomass to a post-processed oil of your choice. We pride ourselves in our ability to offer high efficiency, low labor, turnkey facilities with both production and up-time guarantees.

Maratek's Turnkey Extraction Facility build-outs usually range from 3,000 pounds of cannabis & hemp input material per day to more than 100,000+ pounds per day. With full automation, GMP certification, and C1D1 compliance all built directly into the line.

Do you have existing equipment and technologies? Maratek Environmental’s integration team will develop a customized engineered solution to ensure your existing equipment works seamlessly with Maratek’s systems. Our manufacturing facility and team of in-house engineering puts us at the forefront of design, implementation, integration and service. Speak to a Maratek engineer today or download a Turnkey Extraction Facility brochure (opens PDF).

✅ 3,000 - 100,000+ Pounds per Day of processing

✅ 99%+ Solvent Recovery

✅ Built-in Solvent Reproofing and C.I.P

✅ Over 50 years of Engineering, Design & Manufacturing Experience

✅ Allen Bradley and Siemens PLC controls with data logging & programmable recipes

✅ GMP designs available

✅ C1D1 and C1D2 compliance

✅ 304 & 316 Stainless Steel

✅ Engineered, Designed and Manufactured in Canada

✅ Compliant in all Regulated Jurisdictions

We can seamlessly resolve problems you may encounter right from our office with our remote access PLC. With your permission, we will be able to access your system controls to assist with diagnostics and troubleshooting to minimize downtime. Your organization will also have the same secure remote operational capabilities. Maratek’s Uptime Guarantee utilizes our secure remote troubleshooting technology and the ability to dispatch a technician within 24 hours if your equipment needs on-site service. A variety of service and spare parts packages are available to suit your specific needs. We also offer production throughput guarantees based on your stream parameters and stand behind these values with a money back guarantee.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi non commodo mauris.

Want to learn more about how to scale your cannabis and hemp oil extraction? We have a two-part webinar that you may be interested in.

Read this blog to learn about the many benefits of turnkey engineering solutions in cannabis extraction and how it can help scale your business.

This is the second part of our webinar covering scaling your cannabis and hemp oil extraction. Information is provided in video or blog format.

sales@maratek.com

Canada

39 Nixon Road, Bolton, Ontario

L7E 1K1, Canada

United States

250 Monroe Ave. NW, Suite 400

Grand Rapids, MI, 49503

Mexico

Fuente Bella 3299, 14th Floor, Delegación: Tlalpan

Conjunto Residencial del Pedregal, Mexico City, 14130