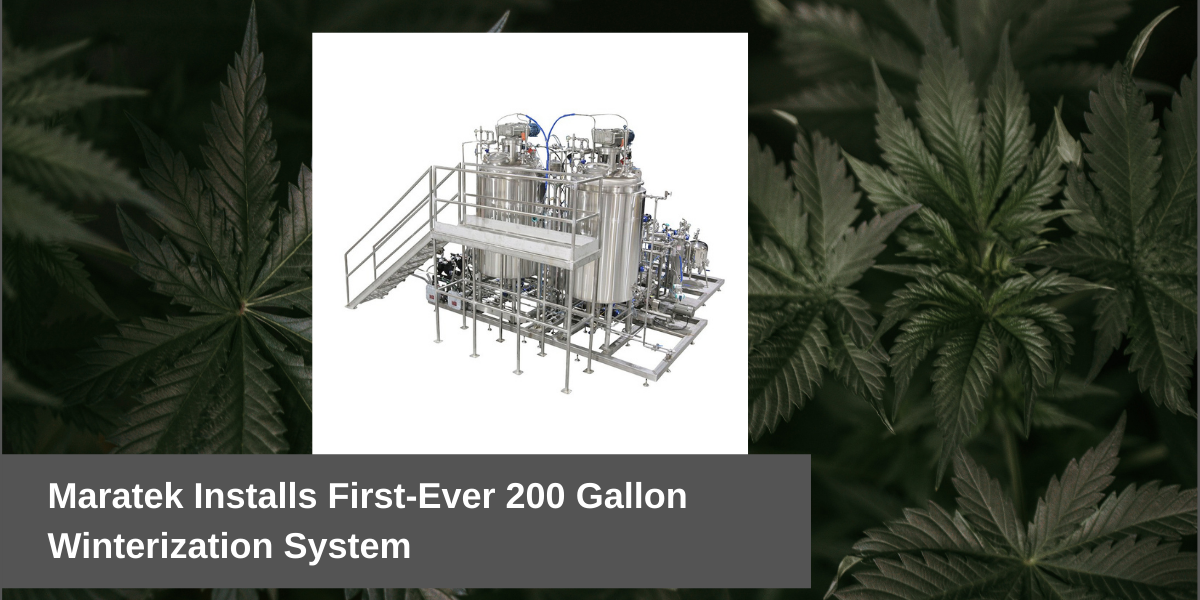

Maratek Installs First-Ever 200 Gallon Winterization System

Maratek is pleased to announce that it has successfully installed and started its first Turnkey Automatic Winterizations System-200 (TAWS-200) over the past few weeks.

This represents a turning point in the industry, allowing the owner of this first-of-a-kind piece of equipment to process up to 200 gallons of homogenized crude extract in one single batch. This has dramatically increased their throughput, moving from 24-hour winterization cycles in walk-in freezers to a 12-hour winterization cycle at much higher quantities.

The necessary workforce to complete winterization has therefore been reduced, with two operators being able to completely manage the TAWS-200. This is down from up to six or eight working on homogenization, winterization, and filtration at any given time. All three steps have been automated significantly in comparison to the previous methods done by the customer.

Automating the entire process

Homogenization previously involved long warming cycles of the raw crude from the CO2 extraction systems to make it easier to dissolve in ethanol. From this, it would be thoroughly mixed by hand or by electric mixer until a homogenized mixture was identified by visual inspection.

This time-consuming, labour-intensive process has been entirely replaced with the automatic homogenization as part of the TAWS-200, where crude can be directly added to the vessel and heated ethanol dissolves the crude. This gives a fully homogeneous product with minimal operator intervention, allowing for their time to be put towards more value-adding duties.

As winterization time has been reduced for the customer, significant savings are found with more batches being possible in the same time frame. There is also no operator intervention required to begin the winterization step, as material can be automatically transferred post-homogenization to the winterization stage.

It is also possible to have the filtration begin automatically at the end of the winterization time, provided that the system detects that all necessary conditions are in place to allow this. These include sufficient volume available in the discharge vessels and no detected blockages in the filtration housings. With these conditions met, filtration proceeds and with a 200-gallon batch, takes just one to two hours to complete through a two-stage filtration process.

The filtration step has undergone many iterations to find an optimized pattern for the fastest filtering of the winterized crude oil. Many filter micron sizes were trialed, and the system was optimized with 100-micron first stage filters followed by a two-micron second stage. This has provided the owner a clear crude product - free of any undesired components.

With insulation provided on all parts of the system that contacts the winterized materials, temperature can be maintained throughout the filtration process. From the start to finish of a two-hour filtering sequence, a temperature rise of 5 degrees, from -40C to -35C, is observed. The owner of the TAWS-200 has found this has no effect on the final quality of the crude extract and there has been consistent analysis showing that no fats or waxes infiltrate the final product.

Want to learn more about our uniquely engineered TAWS equipment? The maratek team of extraction experts would love to answer your questions about how the system works. Contact us today for more information.